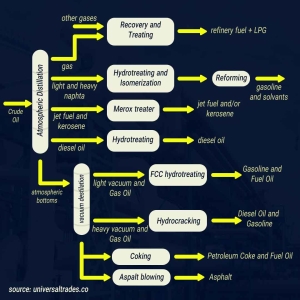

Types of petroleum products and their uses

Petroleum, or crude oil, is a vital natural resource that, through the process of refining, yields a vast array of petroleum products and petroleum derivatives. These products are fundamental to modern life, serving as primary sources of energy, raw materials for countless industries, and essential components in everyday goods. The process of refining separates crude oil into different fractions based on their molecular weight and boiling points.

The most common petroleum products consumed globally include gasoline (petrol) and diesel fuel, which are the mainstays of the transportation sector, followed closely by liquefied petroleum gas (LPG) and kerosene (including jet fuel).

List of Petroleum Products from Lightest to Heaviest

The following list arranges various petroleum products in the approximate order of their increasing molecular weight and boiling point, from the lightest (gases) to the heaviest (solids/semi-solids).

-

LNG (Liquefied Natural Gas): Primarily Methane (C1).

-

LPG (Liquefied Petroleum Gas): Primarily Propane (C3) and Butane (C4).

-

Solvents (Light aliphatic, some included in the Naphtha range).

-

Naphtha (Includes light gasoline fractions).

-

Gasoline (Petrol).

-

Kerosene (Jet Fuel).

-

Diesel (Gas Oil).

-

Lube Cut (A heavy fraction used to make base oil).

-

Base Oil (Lubricants).

-

Paraffin (Wax).

-

Fuel Oil (Heavy fuel oil, Bunker fuel).

-

Sulfur (A byproduct of removing sulfur compounds).

-

Petroleum Coke (Petcoke).

-

Bitumen (Asphalt).

Detailed Introduction to Petroleum Products

LNG (Liquefied Natural Gas) & LPG (Liquefied Petroleum Gas)

LNG is primarily methane (C1), the lightest hydrocarbon, cooled to a liquid state for easy storage and transport. LPG is a mixture predominantly of propane (C3) and butane (C4), liquefied under pressure. Both are used as clean-burning fuels for heating, cooking, and vehicles.

The Meaning of C1, C2, C3, and C4

In the context of petroleum chemistry and refining, C1, C2, C3, and C4 refer to hydrocarbons (alkanes) based on the number of carbon atoms in their molecular chain:

-

C1 (Methane): The simplest hydrocarbon, CH4, the main component of natural gas.

-

C2 (Ethane): A two-carbon chain, C2 H6.

-

C3 (Propane): A three-carbon chain, C3 H8.

-

C4 (Butane): A four-carbon chain, C4 H10 (with n-butane and isobutane isomers).

These light hydrocarbons are the first products separated during the refining process due to their low boiling points.

Naphtha

Naphtha is a flammable liquid mixture of hydrocarbons, typically falling between the light gases and kerosene. It is primarily used as a feedstock in the petrochemical industry to produce olefins (like ethylene and propylene) and as a component for gasoline blending.

Gasoline (Petrol)

Gasoline is a widely used fuel in internal combustion engines. It’s produced through various processes, including atmospheric distillation, catalytic cracking, and alkylation.

-

Gasoline Production Process: The production involves blending various refined components (naphtha, reformate, alkylate, etc.) to meet specific performance requirements.

-

Octane Number: This is a standard measure of a fuel’s ability to resist compression and avoid premature combustion (knocking) in an engine. A higher octane number indicates greater resistance to knocking.

Kerosene (Jet Fuel)

Kerosene is a medium-weight oil fraction, historically used for lighting and heating. Today, its primary use is as jet fuel (Jet A, Jet A-1) due to its suitable properties for high-altitude combustion.

-

Kerosene Production Process: Kerosene is primarily obtained directly from the distillation of crude oil, but it can also be produced through hydrocracking of heavier fractions.

Diesel (Gas Oil)

Diesel fuel is a heavier fraction than kerosene, used to power compression-ignition (diesel) engines.

-

Diesel Production Process: It’s produced primarily through the direct distillation of crude oil, often supplemented by processes like hydrocracking to increase yield and improve quality.

-

Cetane Number: This measures the ignition quality of diesel fuel—its tendency to ignite quickly upon injection. A higher cetane number signifies better ignition performance.

-

Low-Sulfur Diesel: Diesel fuel with a significantly reduced sulfur content, mandated in many regions to decrease harmful sulfur dioxide emissions.

-

Biodiesel: A renewable, clean-burning alternative to petroleum-based diesel, made from vegetable oils, animal fats, or recycled restaurant grease.

Lube Cut and Base Oil

Lube Cut is the heavy distillate fraction from crude oil used as the primary raw material to manufacture Base Oil, the main component of lubricants.

Base Oil Classification (API Groups):

-

-

Group 1 Base Oil: Least refined (solvent-refined), with lower saturate and higher sulfur content. Viscosity Index (VI) of 80–120.

-

Group 2 Base Oil: Better refined (hydrocracked), higher saturate and lower sulfur content. VI of 80–120.

-

Group 3 Base Oil: Very high level of refinement (severe hydrocracked/hydroisomerized), >90\% saturates, <0.03\% sulfur, and VI >120. Often considered “synthetic” in some markets.

-

Group 4 Base Oil: Fully synthetic, based on Polyalphaolefins (PAOs). Excellent performance in extreme temperatures.

-

Group 5 Base Oil: All other base oils not included in Groups I–IV, such as esters, silicone oils, and polyalkylene glycols (PAGs).

-

Paraffin (Wax)

Paraffin is a waxy solid mixture of higher alkanes, obtained from the heavier lubricating oil fractions. It is widely used in candles, protective coatings, and cosmetic products.

Fuel Oil

Fuel Oil is a general term for the heavier distillate and residue fractions used in furnaces, boilers, and large ship engines (often called Bunker Fuel). It is a relatively heavy and viscous petroleum derivative.

Sulfur

Sulfur is an important byproduct of the refining process, as it must be removed from fuels and other products for environmental reasons.

-

Granulated Sulfur: Elemental sulfur processed into solid granules, making it easy to handle, transport, and store. Its main application is in the production of sulfuric acid, a key industrial chemical.

-

Powdered Sulfur: Finely ground elemental sulfur used in agriculture (as a soil amendment, fungicide, and fertilizer component) and in the vulcanization of rubber.

Petroleum Coke (Petcoke)

Petroleum Coke is a carbon-rich solid material derived from the final, heaviest residue in the refining process. It is used primarily as a fuel in power plants and as a raw material for electrodes in the aluminum and steel industries.

Bitumen (Asphalt)

Bitumen is the heaviest, black, sticky residue of crude oil refining, primarily used as the binder in asphalt concrete for road paving and roofing.

-

Bitumen Production Process: It is mainly obtained through the vacuum distillation of the heaviest crude oil residue. Further treatment (like oxidation) can modify its properties.

-

Natural Bitumen: Bitumen that occurs naturally, such as in pitch lakes or oil sands, not derived from refinery processes.

-

Emulsion Bitumen: Bitumen dispersed as fine droplets in water using an emulsifying agent. This allows it to

-

be applied at lower temperatures, reducing energy consumption and risks.

-

Cutback Bitumen: Bitumen whose viscosity has been temporarily lowered by blending it with a solvent (e.g., kerosene or naphtha) to make it easier to apply. The solvent evaporates after application.

-

Oxidized Bitumen (Blown Bitumen): Bitumen that has been treated by blowing air through it at high temperatures, which increases its hardness and softening point, making it suitable for roofing and industrial applications.

Conclusion:

Petroleum products are one of the most important energy sources in the world and are used in many industries and applications. This article presents some of the most widely used petroleum products. It should also be noted that the optimal and sustainable use of petroleum products can help protect the environment and reduce air pollution.

Frequently Asked Questions (FAQ):

1. What products are made from petroleum?

Petroleum products are not limited to just fuels. Many of our everyday items are also derived from petroleum. In addition to gasoline and diesel, plastics (like bottles and containers), synthetic fabrics (such as polyester and nylon), chemicals in cosmetics, and even asphalt for roads are examples of petroleum products.

2. Are Vaseline and mineral oils petroleum products?

Yes, Vaseline (Petrolatum) and mineral oils are byproducts of the petroleum refining process. They are highly refined and purified for use in cosmetic and health products.

3. Are foods or food additives made from petroleum?

Directly, no. Petroleum is not used as a food ingredient. However, some food additives, such as certain food colorings, flavorings, and preservatives, can be produced from petroleum-derived chemicals through complex processes. These additives are strictly purified and controlled to be safe for consumption.

4. Are plastic, lipstick, and perfume made from petroleum?

Yes. Plastics are made from polymers that are mainly derived from naphtha (a petroleum product). Many perfumes contain alcohol and synthetic aromatic compounds that are also derived from petroleum. As for lipstick, it often includes petroleum jelly and mineral oils, which are petroleum products.

5. Why is petrolatum used in some products?

Petroleum jelly is used in many cosmetic and health products, like creams, ointments, and lip balms, due to its water-repellent properties. It creates a protective layer on the skin to prevent moisture loss and dryness.

6. Are candles made from petroleum?

Yes, most common candles, known as paraffin wax candles, are made from paraffin, which is a petroleum product. Paraffin is a white, solid wax derived from crude oil.

7. Is cooking oil made from petroleum?

No. Cooking oils are derived from plant sources like sunflower seeds, olives, soybeans, and so on, and have no connection to petroleum products.

8. Is petroleum a renewable resource?

No, petroleum is a non-renewable energy source. It was formed over millions of years from the remains of living organisms, and it is being consumed much faster than it can be replenished.

9. What are the uses of petroleum products in our daily lives?

Petroleum products are much more than just vehicle fuels. They are used in the production of many items we use every day, such as plastics, cosmetics, certain medications, paints, and even some clothing fibers.

10. What is the main difference between gasoline, diesel, and mazut?

The main difference lies in their distillation process and hydrocarbon structure. Gasoline is made of lighter hydrocarbons and is suitable for gasoline engines. Diesel consists of heavier hydrocarbons and is used for diesel engines. Mazut (fuel oil) is composed of the heaviest hydrocarbons and is used as an industrial or marine fuel.

11. Why is asphalt suitable for road construction?

Asphalt is an ideal material for road construction due to its high adhesive properties and water resistance. Its flexibility also makes it resistant to temperature changes and cracking, which helps extend the lifespan of roads.

12. Is LNG (Liquefied Natural Gas) the same as LPG (Liquefied Petroleum Gas)?

No, they are different. LNG is primarily methane that has been liquefied for transportation at extremely low temperatures, whereas LPG is a mixture of propane and butane that is liquefied under pressure and used as fuel for vehicles or homes.

I read this article and realized that base oil is really important in the oil industry. But what exactly is the difference between it and what we usually call a “lubricant” or “lubricating oil”? I mean, is every oil we buy considered a lubricant, or are they different?

That’s an excellent question! Essentially, all lubricants (like engine oil or gear oil) are made from base oil, but base oil itself isn’t a complete lubricant on its own.

Think of base oil like flour in baking. You can make all sorts of bread, cakes, or pastries with flour, but flour alone doesn’t have those final properties. Base oil serves as the primary raw material for manufacturing lubricants.

For base oil to become a finished, usable lubricant, various chemical additives are blended into it. These additives are what provide specific properties to the final oil (the lubricant), such as resistance to high temperatures, enhanced wear reduction, rust prevention, or cleaning capabilities. For example, the engine oil you buy for your car is a blend of base oil and many additives that enable it to perform under engine conditions.

So, the main difference is: Base oil is the core raw material of lubricants, whereas lubricants are the finished products, formulated by combining base oil with additives for specific applications.

Thank you for this comprehensive and practical article! You’ve truly provided valuable information about petroleum products and their diverse applications. Given that asphalt has different types categorized by penetration grade, and they have varying applications for hot and cold regions, could you elaborate on how the appropriate type of asphalt is chosen for a specific project (e.g., road paving in a region with highly fluctuating weather conditions)?

You’re most welcome; I’m glad the article was useful! Selecting the right asphalt for a project, especially in regions with fluctuating weather, is crucial and depends on several factors:

Climatic Conditions:

Hot Regions: To prevent the asphalt from softening and deforming at high temperatures, lower penetration grade asphalts (harder) are used. These asphalts offer greater resistance to rutting.

Cold Regions: In these areas, to prevent cracking caused by thermal contraction and expansion, higher penetration grade asphalts (softer and more flexible) are employed.

Regions with Fluctuating Weather: In such regions, which experience both high and low temperatures, polymer-modified bitumens (PMB) are often used. The addition of polymers improves asphalt properties, including increased resistance to cracking in cold weather and resistance to deformation (rutting) in hot weather. These asphalts offer greater flexibility and durability.

Traffic Volume and Load Type:

Roads with heavy traffic and high loads (like highways) require more robust and durable asphalts that can withstand the stresses of traffic. In these cases, polymer-modified bitumens or lower penetration grade asphalts might be better choices.

For roads with lighter traffic, more standard asphalts can be used.

Project Type and Asphalt Layer:

The asphalt used in different layers of pavement (such as the base, binder, and surface course) may vary. Each layer requires different asphalt properties to optimize the overall pavement performance.

In summary, in regions with highly fluctuating weather and for critical projects like road paving, civil consultants and engineers consider all these factors, using relevant tests and standards, to select the appropriate asphalt type. The use of polymer-modified bitumens in these conditions is increasingly common due to their ability to provide a balance between heat resistance and cold-weather flexibility.

The article mentions Base Oil is crucial for lubricants. What is the fundamental difference in the refining process that distinguishes high-quality Base Oil from simple Fuel Oil (Mazut), given that both come from the heavier cuts?

The difference lies in the intensive purification. While Mazut is simply a heavy residue used for fuel, Base Oil undergoes additional, specialized processes like hydrocracking, solvent extraction, and dewaxing to remove impurities (sulfur, aromatics, nitrogen) and improve its Viscosity Index (VI) and oxidative stability, making it suitable for long-term lubrication.

A very comprehensive list! I appreciate the mention of Naphtha as a bridge between fuel and chemicals. In the 2026 market, we are seeing a trend where refineries are maximizing Naphtha production over Gasoline to feed the growing demand for Ethylene and Propylene. Does Universal Trades offer both Light and Heavy Naphtha? And how do you ensure the Paraffin content is high enough for steam cracking efficiency?

Hello Dr. Chen, thank you for your professional input. You’re right—the “Chemical Integration” of refineries is a major trend this year. We do supply both Light Naphtha (ideal for ethylene crackers) and Heavy Naphtha (perfect for catalytic reforming). To ensure maximum efficiency for our clients, our quality control team checks the PONA analysis (Paraffins, Olefins, Naphthenes, Aromatics) for every batch, prioritizing high paraffinic content for petrochemical applications.