Group 1 Base Oil: Properties, Grades and Applications

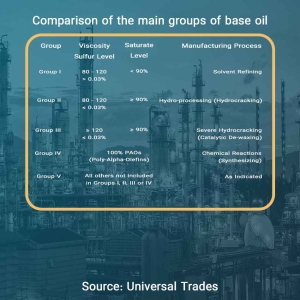

Base oil is the foundation of any lubricant, making up 60% to 90% of its volume. Critical lubricant properties like viscosity, oxidation stability, solubility, and volatility are directly influenced by the quality of the base oil. The American Petroleum Institute (API) categorizes base oils into five groups (I to V) based on their saturate levels, sulfur content, and Viscosity Index (VI). Higher saturate levels, lower sulfur, and a higher VI generally indicate better quality.

Group I base oils are the oldest and most traditional type, produced through a solvent refining process. This process involves fractional distillation, solvent extraction to remove unwanted compounds like sulfur and aromatics, followed by dewaxing to eliminate waxy paraffin molecules.

Definition and Characteristics of Group I Base Oils

Group I base oils are defined by the following specifications:

- Saturate Level: Less than 90%

- Sulfur Content: Greater than 0.03%

- Viscosity Index (VI): Between 80 and 120

These oils are primarily derived from paraffinic crude oil.

Key Properties:

- Color: Amber to golden brown (due to residual sulfur, nitrogen, and cyclic compounds).

- Volatility: Relatively low.

- Solvency: High, which is crucial for dissolving additives in lubricants.

- Lubricity: Possess good inherent lubricating properties to reduce friction and wear.

- Oxidation Stability: Good, though less superior compared to Group II and III oils.

- Flash Point: High.

- Low-Temperature Properties: Suitable, but may have limitations in extremely low temperatures.

- Typical Operating Temperature Range: Approximately 0 to 65.5°C (32 to 150°F).

Advantages and Limitations

Advantages:

- Accessibility and Cost-Effectiveness: Their simpler production process makes them readily available and economically attractive.

- Versatility: Widely used in hydraulic systems, gearboxes, and general industrial lubricants.

- Good Solvency: Excellent solvency for additives is a significant advantage in lubricant formulation.

Limitations:

- Lower Performance: Not recommended for high-performance applications or severe operating conditions (e.g., modern automotive engines).

- Weaker Antioxidant Properties: Inferior to Group II oils, which undergo more severe hydrocracking.

- Limitations in Extreme Pressure/Low-Temperature Applications: May not provide adequate performance in very low temperatures or under extreme pressures.

- Darker Color: Their lower purity results in a darker color compared to higher groups.

Group I Base Oil Grades (SN and Bright Stock)

Group I base oils are available in various grades, primarily categorized by their viscosity. SN (Solvent Neutral) grades and Bright Stock are the most common. SN grades are typically named based on their approximate kinematic viscosity at 40°C. A higher number after “SN” indicates higher oil viscosity. This viscosity directly determines the oil’s suitability for different applications requiring specific film thickness and load-carrying capacity.

Explanation and Applications of Each Base Oil Grade

Here’s a detailed explanation of the common Group I base oil grades and their applications:

SN 60/70/80 Base Oil:

- Description: These are the lighter Group I base oils, with parameters at the lower end for general lubricants.

- Applications: Primarily used in general applications where very high viscosity or specific performance is not required.

SN 100 Base Oil:

- Description: SN100 is a light base oil derived from further processing of specific crude oil vacuum distillates. This grade is at the lower end of the viscosity specifications for Group I light base oils.

- Applications: Widely used in the production of lubricants and lubricant additives. It is suitable for a wide range of automotive and industrial lubricants. Specific applications include general oils, mold oils, power transmission fluids, gear oils, metalworking fluids, additives, hydraulic oils, and transformer oils. It also finds use in soluble and neat cutting oils, textile lubricants such as spinning oils, and agricultural spray oils.

SN 150 Base Oil:

- Description: SN150 is a medium viscosity base oil obtained from further processing of specific crude oil vacuum distillates. This grade also falls at the lower end of the specifications for Group I light base oils. It is produced through solvent extraction and dewaxing processes, and also hydrogen-treated to further remove impurities.

- Applications: Often used in the production of high-quality lubricants, including hydraulic oils, transformer oils, and other industrial lubricants. It’s also used for formulating gasoline and diesel engine oils, greases, and specialty products. Similar applications to SN100, such as general oils, mold oils, power transmission fluids, gear oils, metalworking fluids, and additives, also apply to this grade.

SN 300 Base Oil:

- Description: SN300 is known for its higher viscosity. This grade is also derived from further processing of specific crude oil vacuum distillates. To ensure purity, this oil is solvent-refined, dewaxed, and hydrogen-treated. Its properties include high thermal stability and a long service life.

- Applications: Widely used in the manufacturing of engine oils, gear oils, and heavy-duty lubricants. General industrial applications, mold oils, power transmission fluids, metalworking fluids, additives, hydraulic oils, and transformer oils are also among its uses. Additionally, it is employed in soluble and neat cutting oils, textile lubricants such as coning oils, antistatic oils, spin finish oils, shoe polish, pigments, and agricultural spray oils.

SN 500 Base Oil:

- Description: SN500 is a heavier base oil with high viscosity, sitting at the higher end of the viscosity specifications for Group I base oils. This grade also results from further processing of specific crude oil vacuum distillates.

- Applications: Ideal for producing advanced lubricants, engine oils, and greases that require greater consistency and thickness. It has extensive applications in the production of engine oils, power transmission fluids, gear oils, metalworking fluids, greases, hydraulic oils, and transformer oils.

SN 600/650 Base Oil:

- Description: SN 600/650 is a base oil at the highest end of the specifications for Group I base oils. This grade is produced through solvent refining and dewaxing processes.

- Applications: Generally used in the production of lubricants and lubricant additives. Its applications include gasoline and diesel engine oils, dual-fuel and gas engine oils, industrial lubricants, grease, and specialty products. It is also used in power transmission fluids, gear oils, metalworking fluids, greases, hydraulic oils, and transformer oils.

Bright Stock (BS 150):

- Description: Bright Stock is a very high viscosity Group I base oil, derived from further processing of specific crude oil vacuum distillates. These oils fall into the category of high viscosity index (HVI) base oils. Bright Stock undergoes solvent refining, dewaxing, and hydrogen treatment to remove impurities and enhance its properties.

- Properties: Features high oxidation stability, good additive response, low sulfur content, and excellent viscosity-temperature characteristics. These properties make it suitable for demanding applications.

- Applications: Traditionally used in blending heavy industrial lubricants, marine oils, and greases. It also finds application in the production of engine oils, additives, gear oils, power transmission fluids, metalworking fluids, hydraulic oils, and transformer oils. Due to its high viscosity and excellent thermal stability, Bright Stock is used in specific applications where these properties are of particular importance. This demonstrates that Bright Stock, despite the overall decline of Group I base oils in certain sectors, has maintained a crucial and stable position. Its value is based on its inherently high viscosity and excellent thermal stability, which are vital for heavy-duty applications where strong film thickness and high-temperature performance are essential.

I’m looking at the specs. How exactly does the solvent refining process give Group I oils better solvency for additives compared to the purer Group II and III oils?

That’s a great question about the trade-off! Solvent refining doesn’t remove all the aromatics and polar compounds. These leftover compounds are precisely what gives Group I base oils their excellent solvency. The purer Group II/III oils (produced by hydroprocessing) have much lower amounts of these compounds, making it sometimes harder to dissolve certain additives fully.