Base Oil Grades and Their Applications

Base oil is one of the most crucial petroleum products, serving as the primary constituent (typically 75% to 99%) in the formulation of lubricants. Lubricants are essential substances designed to reduce friction and wear between moving surfaces in machinery, extending equipment life and enhancing efficiency. While petroleum products like gasoline, diesel, and kerosene are primarily used as fuels, base oil is the functional backbone of almost all industrial and automotive lubricating fluids. A correct understanding of base oil grades, classified by the American Petroleum Institute (API), is vital for selecting the appropriate lubricant for any application.

What is Base Oil?

Base oil is a refined fraction derived from crude oil (with the exception of synthetic Group IV and some Group V oils). It is the liquid component that remains after lighter fractions, such as gasoline and kerosene, have been removed during the refining process. The quality of the final base oil depends heavily on the refining method, which aims to remove undesirable compounds like waxes and impurities, especially those containing sulfur. The resulting product is characterized by key parameters, including its Viscosity Index (VI), saturation level, and sulfur content, which determine its classification into one of five API groups.

Base Oil vs. Crude Oil

Crude oil is the raw, unrefined liquid mixture of hydrocarbons extracted from the earth. It is a highly variable substance, containing everything from light gases to heavy materials like bitumen, along with significant quantities of impurities, including high levels of sulfur. It is not directly usable as a lubricant component.

Base oil, conversely, is a highly refined petroleum product derived from crude oil. Through processes like fractional distillation, hydrocracking, and solvent refining, the undesirable elements in crude oil are minimized, resulting in a stable, functional hydrocarbon fluid suitable for blending with additives to create a finished lubricant.

The Chemical Formula of Base Oil

Base oils are primarily complex mixtures of hydrocarbons, not a single chemical entity, so they do not have a simple, fixed chemical formula like H2 O.

-

Mineral (Group I, II, III) Base Oils: These consist mainly of saturated hydrocarbons, which are long chains (paraffinic) or rings (naphthenic) of carbon and hydrogen atoms. The general empirical formula for an alkane (a type of paraffin) is Cn H(2n+2), but the specific molecules in base oil are much larger, with the carbon number n typically ranging from C 18 to C 40

-

Synthetic (Group IV) Base Oils: Group 4 base oil (PAO) are synthesized from smaller, uniform molecules (alpha-olefins), providing a highly consistent structure.

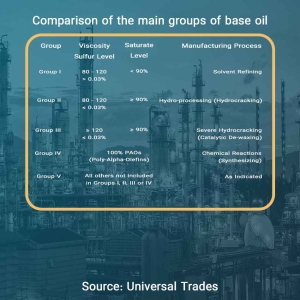

API Base Oil Group Classification

The API classification system divides base oils into five groups based on their level of refinement, saturation, sulfur content, and Viscosity Index (VI).

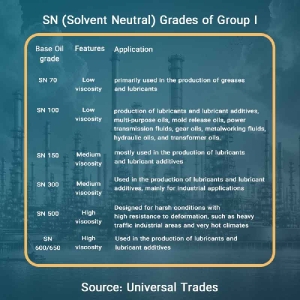

Group 1 Base Oil

-

Production: Solvent refining.

-

Characteristics: Saturation 90%, sulfur 0.03%, VI 80 to 120.

-

Use: General industrial applications, older engine oils, and as a component in lower-cost lubricants. Includes common grades like SN 150 and Bright Stock (BS).

Group 2 Base Oil

-

Production: Hydrocracking.

-

Characteristics: Saturation 90%, sulfur <0.03, VI 80 to 120 (often >100).

-

Use: Modern conventional and semi-synthetic engine oils. They offer better performance and oxidation stability than Group 1 base oil.

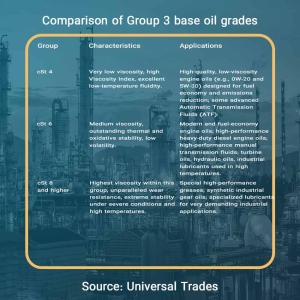

Group 3 Base Oil

-

Production: Severe hydrocracking and hydroisomerization.

-

Characteristics: Saturation >90%, sulfur <0.03%, VI >120.

-

Use: Used to formulate high-performance synthetic or semi-synthetic oils due to excellent thermal and oxidation stability.

Group 4 Base Oil

-

Production: Chemical synthesis (Polyalphaolefins or PAO).

-

Characteristics: Fully synthetic, high VI (typically 125 to 200), excellent performance in extreme temperatures (very hot or very cold).

-

Use: High-end synthetic engine oils, racing oils, and lubricants for severe operating conditions.

Group 5 Base Oil

-

Production: Diverse, depending on the type (e.g., esterification for esters).

-

Characteristics: Includes all other base oils not in Groups I-IV, such as esters, Polyalkylene Glycols (PAGs), and naphthenic oils.

-

Use: Specialized applications (e.g., aviation, refrigeration) and as performance-enhancing additives for other base oils.

Best Types of Base Oil

There is no single “best” base oil; the best choice depends entirely on the application:

-

For Extreme Performance (High/Low Temp): Group 4 base oil (PAO) and some specialized Group 5 base oil (e.g., esters) are superior due to their tailored molecular structure and stability.

-

For Modern Automotive Use: Group 3 base oil offers the best balance of high VI, thermal stability, and cost-effectiveness for most modern synthetic engine oils.

-

For Cost-Sensitive Industrial Use: Group 2 base oil is often preferred over Group 1 base oil because it provides significantly better oxidation stability and purity at a marginal increase in cost. Group 1 base oil is generally considered the lowest quality.

Quality Assessment: Appearance and Laboratory Analysis

The difference between a quality and a poor-quality base oil is evident in both simple observation and detailed laboratory testing.

| Feature | Quality Base Oil (Groups II, III, IV) | Poor-Quality Base Oil (Group I) |

| Appearance | Clear, pale, or water-white; highly consistent. | Often darker, yellow to amber; may appear hazy or inconsistent. |

| Purity/Refinement | Highly refined; very low sulfur and low aromatic content. | Less refined; higher sulfur and higher aromatic content. |

| Viscosity Index (VI) | High (VI >100 or >120 for Group III). | Lower (VI 80 to 120). |

| Oxidation Stability | Excellent; resists thickening and breakdown for longer periods. | Fair/Poor; oxidizes more readily, leading to sludge formation. |

| Lab Test (GC/HPLC) | Shows a narrow, uniform molecular structure. | Shows a broad range of inconsistent molecules and impurities. |

Conclusion

Base oil, a crucial derivative of crude oil and a core petroleum product, is fundamental to the world of lubrication. The API classification system, ranging from the less-refined Group 1 base oil to the high-performance Group 4 base oil and specialized Group 5 base oil, guides the lubricant industry. The shift toward modern, highly-refined base oils (Group 2 base oil and Group 3 base oil) reflects the industry’s need for enhanced thermal stability and reduced impurities, paving the way for better performing lubricants and extending the life of machinery. Understanding the properties of each group is essential for maximizing efficiency in automotive and industrial sectors.

Frequently Asked Questions (FAQ)

1. What is base oil and why is it important?

Base oil constitutes the main part (approximately 75-99%) of lubricants and is used to reduce friction and wear between moving parts of machinery. The quality and type of base oil directly impact the final performance of the lubricant and the lifespan of the equipment.

2. How does API classify base oils?

The American Petroleum Institute (API) classifies base oils into five main groups (I, II, III, IV, and V) based on three key parameters: saturation level, sulfur content, and Viscosity Index.

3. What are the main differences between Group I, II, and III base oils?

- Group I: Least refined, high sulfur, Viscosity Index between 80-120. Used for general and cost-effective applications.

- Group II: More refined (hydrocracking), low sulfur, Viscosity Index usually above 100. Better oxidation stability and higher quality.

- Group III: Most refined (severe hydrocracking), very low sulfur, Viscosity Index above 120. Excellent thermal and oxidation stability, suitable for high-quality synthetic engine oils.

4. What are the characteristics of Group IV and V base oils?

- Group IV: Fully synthetic oils (PAO) with a high Viscosity Index (125-200). Excellent stability at very high and low temperatures, suitable for ultra-high-performance applications.

- Group V: Includes all base oils not in other groups, such as esters, PAGs, and naphthenic oils. They have diverse properties and are used for specialized applications or as additives.

5. Is edible oil produced from base oil?

No, edible oil is not produced from base oil. Base oil is derived from crude oil refining and is used for industrial and lubrication purposes. Edible oils come from plant sources (e.g., sunflower, olive, soybean) or animal sources (e.g., animal fats) and undergo completely different refining processes for food consumption.

6. Which type of base oil is the best?

There is no “best” type of base oil; the best type depends on the specific application. For general and cost-effective uses, Group I or II are suitable. For advanced engine oils and operation in high and low temperatures, Group III or IV (synthetic) offer the best performance. Group V is used for very specialized properties. The correct choice is determined by equipment needs and operating conditions.

7. Is base oil used for massage?

It depends on the type of base oil, but generally, industrial base oil is not suitable for massage. Some “white oils,” a subset of Group V base oils (naphthenic) with very high purity, used for pharmaceutical and cosmetic purposes (like baby oil or lotions), might be used as a base for massage oils. However, regular industrial base oils contain impurities that can be harmful to the skin and should never be used directly for massage.

It’s fascinating how base oil makes up such a large percentage of lubricants—up to 99%! I’d be curious to learn more about how different base oil grades affect lubricant performance in extreme conditions.

The fact that base oil can make up to 99% of the volume of a lubricant is truly fascinating and demonstrates its fundamental importance. This high percentage clearly states that the quality and type of base oil will be the main determinant of the ultimate performance of the lubricant, especially in severe conditions.

Given the API base oil classification (Groups I to V) explained in the article, if I want to choose a high-quality engine oil or lubricant for a modern vehicle operating under severe conditions (like heavy traffic or very hot climates), or for sensitive and expensive industrial machinery, which group of base oils should I opt for, and why?

This is a very important question, as selecting the appropriate base oil directly impacts the performance, longevity, and protection of your engine or machinery under severe conditions. Based on the API classification described in the article:

For modern vehicles operating under severe conditions (heavy traffic, hot climates) or for sensitive and expensive industrial machinery, you should opt for Group III (Group III) or Group IV (Group IV) base oils.

Why?

Group III Base Oils:

Characteristics: These oils feature very high purity, excellent thermal and oxidation stability, and a Viscosity Index (VI) above 120. The article notes that due to their severe refining process, they are sometimes referred to as “synthetic oils.”

Application in Severe Conditions: This group is designed for the production of high-quality, low-viscosity engine oils (such as 0W-20 and 5W-30) that aim to improve fuel efficiency and reduce emissions. Their high thermal stability ensures they retain their properties in high temperatures and heavy traffic conditions, protecting the engine from wear and deposit formation. For sensitive industrial equipment, the high stability and extended life of these oils are crucial.

Group IV Base Oils (PAO – Polyalphaolefins):

Characteristics: These are fully synthetic oils produced through a chemical synthesis process (not from crude oil refining). They have a VI between 125 and 200 and exhibit very high oxidation stability at extreme high and low temperatures. They also have a very low pour point.

Application in Extremely Severe Conditions: Group IV oils are designed for the most demanding operating conditions. If your equipment or vehicle is exposed to very extreme temperatures (both hot and cold) or requires maximum protection and performance (such as racing cars or heavy-duty equipment under high pressure), PAOs are the best choice. Extended oil life and unparalleled component protection are key features of this group.

Conclusion:

If you are looking for “high quality” and “maximum protection” under severe conditions, Group III (for high-quality engine oils and advanced industrial lubricants) and especially Group IV (for superior performance in extremely harsh conditions) are the best options. Group I and II oils are more cost-effective alternatives but are suitable for more common applications and do not offer optimal performance and protection under severe conditions.

will the current industry trend towards increasing use of “Group II and III Base Oils” (which are cleaner and offer higher performance) and the gradual reduction in the share of “Group I Base Oils” significantly impact the global base oil supply chain and their pricing mechanisms in the near future? And what opportunities and challenges will this transformation bring for major base oil suppliers and buyers?

Yes, absolutely, the global industry’s trend towards Group II and III base oils and the reduced share of Group I will have significant impacts on the global base oil supply chain and pricing mechanisms. This shift is not just an ongoing trend but will also accelerate due to stricter environmental regulations and advancements in engine technology.

Heya i am for the first time here. I found this board and I find It really useful & it helped me out much. I hope to give something back and help others like you aided me.