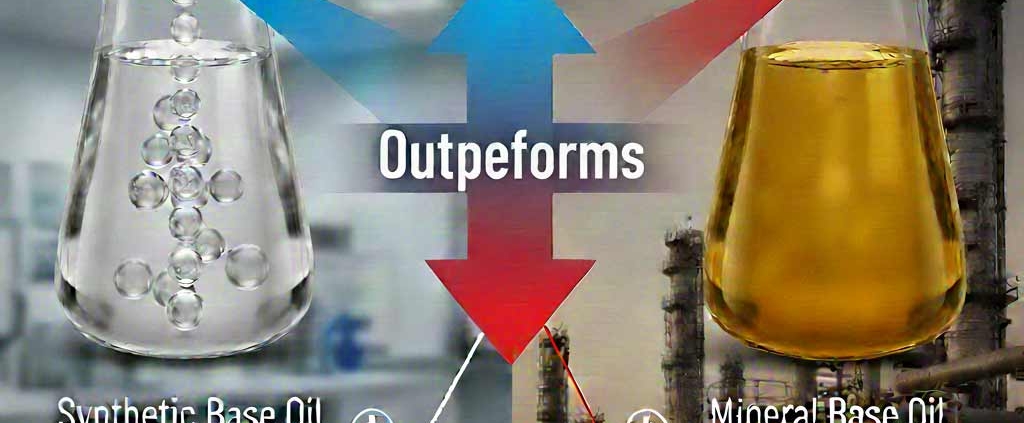

What is Synthetic Base Oil and Why Does It Outperform?

Synthetic base oil is a man-made lubricant designed through chemical synthesis rather than traditional distillation. Unlike mineral base oil, which is refined from crude oil, synthetic oils are built from the ground up. Scientists break down petroleum molecules and rebuild them to create a uniform molecular structure. This consistency allows the oil to perform under extreme conditions where natural oils might fail.

Synthetic vs. Mineral Base Oil: The Comparison

The primary difference lies in the molecular structure. Mineral oil contains molecules of various sizes and shapes, along with impurities like sulfur and oxygen. Synthetic oil consists of uniform molecules, which leads to lower friction and better thermal stability.

Advantages and Disadvantages

| Feature | Mineral Base Oil | Synthetic Base Oil |

| Cost | More affordable and widely available. | More expensive due to complex processing. |

| Performance | Good for older engines and standard conditions. | Exceptional in extreme heat or freezing cold. |

| Longevity | Requires more frequent oil changes. | Resists breakdown; allows for longer drain intervals. |

| Purity | Contains natural impurities like wax and sulfur. | Highly pure with no wax content. |

| Protection | Provides basic lubrication for petroleum products. | Superior protection against engine wear and sludge. |

Types of Regular (Mineral) Base Oil

Mineral oils are categorized by the American Petroleum Institute (API) based on their refining process and purity levels. Understanding these is key to knowing the types of base oil available:

-

Group 1 Base Oil: The least refined type, produced by solvent refining. It contains more than 0.03% sulfur and has a viscosity index between 80 and 120. It is often used in less demanding industrial applications.

-

Group 2 Base Oil: Produced using hydrocracking, which clears out more impurities. It has better antioxidation properties and is common in modern automotive engine oils.

-

Group 3 Base Oil: These undergo severe hydrocracking (high pressure and heat). While technically derived from crude oil, their performance is so high that they are often marketed as “synthetic” in many regions.

A common technical distinction in this category is the difference between paraffinic and naphthenic base oil, where paraffinic oils are preferred for engine lubricants due to their higher viscosity index.

Types of Synthetic Base Oil

Synthetic oils are generally classified into two main groups based on their chemical origin:

Group 4 Base Oil (PAO)

Polyalphaolefins (PAOs) are the most common major synthetic base oils. They are created by polymerizing alpha-olefin molecules. They offer excellent stability, low volatility, and perform exceptionally well in cold starts.

Group 5 Base Oil

This is a “catch-all” category for any base oil not included in the previous groups. This includes Esters, Polyalkylene Glycols (PAGs), and Silicone. Esters are frequently used as additives to PAOs to improve seal swell and solubility.

The Process of Producing Synthetic Base Oil

The production of synthetic oil is a complex chemical engineering feat. It typically starts with the byproduct of gasoline or diesel refining, such as ethylene gas.

-

Cracking: Large hydrocarbon chains from crude oil are broken down into small, uniform gaseous molecules.

-

Synthesis (Polymerization): These small molecules (monomers) are chemically reacted to build long-chain polymers. Unlike the distillation used for kerosene or bitumen, this process ensures every molecule is the same size.

-

Additive Blending: Once the base fluid is created, it is blended with performance additives to handle specific tasks like rust prevention and cleaning.

Excellent breakdown of API groups. One technical detail I’d like to highlight is the synergistic effect of Group V (Esters) when blended with PAOs. While PAOs are superior in stability, they sometimes cause seal shrinkage. Adding a small percentage of Esters improves seal swell and solubility of additives. For large-scale blenders, what is the most stable ratio of PAO to Ester you recommend for high-performance racing oils in 2026?

Hello Dr. Carter, thank you for bringing up the “Seal Swell” issue, which is a common concern in advanced tribology. Typically, a blend of 10-15% Ester within a PAO base provides the perfect balance of solvency and seal compatibility. At Universal Trades, we provide high-purity Base Oils that allow blenders to achieve these precise ratios, ensuring the lubricant remains stable even under the extreme pressures of high-RPM racing engines.