Modified Bitumen Roofing: The Ultimate Guide for Durable, Low-Slope Solutions

Modified bitumen roofing, frequently referred to as “mod-bit,” represents a pivotal advancement in the realm of commercial and low-slope residential roofing. This sophisticated asphalt-based system has significantly evolved from its predecessors, offering enhanced performance characteristics vital for contemporary architectural and environmental demands.

1. Introduction: What is Modified Bitumen Roofing?

Modified bitumen roofing is a specialized asphalt-based roofing material meticulously engineered for flat or low-slope roofs. It is created by blending traditional roofing asphalt (bitumen) with advanced polymerized rubber or plastic additives. This modification fundamentally enhances the material’s durability, flexibility, and resistance to various environmental stresses.

This roofing solution is often considered the “progressive relative” or “modern alternative” to traditional built-up roofing (BUR) systems, which have been a staple for over a century. While BUR systems historically consisted of alternating layers of bitumen and reinforcing fabric, modified bitumen streamlines this process by integrating polymers and reinforcing mats into a cohesive, yet highly resilient, waterproof membrane. This development was a deliberate effort to address common challenges associated with traditional BUR, thereby improving overall performance and simplifying installation procedures.

The core purpose of modified bitumen roofing is to provide robust, long-lasting weather protection for flat and low-slope roof structures. Introduced in Europe during the 1970s, it rapidly gained widespread popularity in the United States. Its exceptional tensile strength, remarkable longevity, and relatively straightforward installation process have established it as a preferred solution for countless projects globally, offering a contemporary and reliable alternative to conventional roofing materials. The narrative of its evolution from a proven, century-old system like BUR, while emphasizing its “modern” and “advanced” nature, effectively conveys a sense of reliability stemming from its established track record, combined with the superior performance delivered by modern modifications. This approach helps to build confidence in modified bitumen as a refined and improved solution, rather than an entirely new and untested material, suggesting that the roofing industry has leveraged past experiences to develop a more efficient, effective, and dependable solution for current building requirements.

2. The Science Behind the Strength: Understanding Modified Bitumen’s Composition

The superior performance attributes of modified bitumen roofing systems are a direct result of a sophisticated blend of materials. Each component plays a crucial role in contributing to the membrane’s overall strength, flexibility, and resilience, providing a deeper understanding of why modified bitumen excels in demanding roofing applications.

Bitumen’s Fundamental Properties

Bitumen, commonly known as asphalt, is a naturally occurring or crude oil-derived material characterized by its viscous, adhesive, and waterproofing properties. As one of many vital petroleum products extracted during the refining of crude oil—a process that also yields fuels like gasoline, kerosene, and liquefied petroleum gas, as well as lubricants such as base oil—bitumen stands out for its unique physical characteristics. From a chemical perspective, it is a complex mixture primarily composed of hydrocarbons and their derivatives, with carbon constituting 80-88 weight percent and hydrogen ranging from 8-11 weight percent. It also contains varying trace amounts of sulfur, nitrogen, oxygen, vanadium, and nickel. Bitumen is a low-cost thermoplastic material, meaning it softens when heated and hardens upon cooling, typically remaining very viscous or nearly solid at ambient temperatures.

While bitumen’s inherent properties—such as its adhesiveness, waterproofing capabilities, and thermoplasticity—make it a foundational roofing material, its limitations, particularly its susceptibility to temperature extremes (becoming brittle in cold and overly soft in heat) and its tendency to age, necessitate modification for enhanced, long-term performance across diverse climates.

The Role of Polymer Modification

The term “modification” in modified bitumen refers to the deliberate and strategic blending of standard bitumen with specialized polymers, such as Styrene-Butadiene-Styrene (SBS) or Atactic Polypropylene (APP). This process involves either mechanical mixing or chemical reactions, which fundamentally alters the bitumen’s internal structure, creating a unique matrix that significantly enhances its physical properties. Typically, the polymer content ranges from 3% to 10% by weight of the bitumen.

Polymers are macromolecules formed from smaller repeating units called monomers. The two most frequently employed asphalt modifiers in modified bitumen membranes are Atactic Polypropylene (APP) and Styrene-Butadiene-Styrene (SBS). These elastomers or plastomers are carefully selected to dramatically transform the bitumen’s characteristics. This is not merely a simple addition of ingredients; it represents a sophisticated approach to material science, often termed “performance engineering.” The specific molecular structures of SBS (an elastomer, imparting rubber-like properties ) and APP (a plastomer, providing plastic-like characteristics ) are chosen precisely to impart desired properties like flexibility, UV resistance, and temperature stability that bitumen alone cannot achieve. This deliberate engineering ensures that modified bitumen is not just “asphalt with additives,” but a precisely designed material optimized to overcome the inherent limitations of traditional bitumen, leading to superior and predictable performance in real-world roofing conditions.

The polymer modification imparts several critical improvements to the bitumen’s binder properties:

- An increased softening point and enhanced high-temperature resistance to flow, ensuring the material remains stable in hot conditions.

- Improved low-temperature flexibility and elasticity, allowing it to remain pliable and functional even in cold temperatures.

- Greater elasticity and resilience, enabling the material to stretch and recover its original form, similar to rubber.

- Improved aging characteristics and increased resistance to general aging and weathering effects.

- Enhanced resistance to cracks and leaks that might otherwise be caused by structural movements or impacts.

Reinforcement Materials

Modified bitumen sheets are not simply polymer-modified asphalt; they are composite sheet membranes. These membranes are reinforced with one or more plies of fabric, which are essential for providing structural integrity, tensile strength, and puncture resistance. This reinforcement ensures that the membrane maintains its shape and integrity under various stresses.

Modified bitumen membranes have evolved to incorporate a diverse range of reinforcement types, each offering distinct physical and performance characteristics:

- Polyester: Features longer bonded strands of polyester fiber, which provide durability, excellent resistance to puncture, and greater elongation. This property is particularly beneficial during building movement and thermal cycling, as it allows the membrane to stretch without fracturing.

- Fiberglass: Characterized by shorter fibers embedded in a rigid binder, fiberglass offers higher tensile strength due to its more rigid nature. It is inherently non-flammable and highly resistant to heat and fire, significantly contributing to the roof’s overall safety profile.

- Composite: This type combines fibers from both polyester and fiberglass, aiming to offer a unique balance of strength and flexibility properties. While typically associated with a higher product cost, composite reinforcements leverage the best attributes of both materials.

Manufacturers must ensure a suitable degree of compatibility between the bitumen and the chosen polymer, and that a thorough, homogeneous mix has been achieved. The careful selection and combination of bitumen type, polymer type, and the percentage of polymer used are critical factors that determine the ultimate physical properties and long-term performance of the modified bituminous “binder”. The description of modified bitumen as a “composite sheet membrane” and a “two-phase system” (bituminous and polymeric matrices ) highlights that its strength originates from the synergistic interaction of its components. For instance, the “continuous rubber network” formed by SBS within the bitumen matrix is a prime example of this synergy. The combination of polymer-modified bitumen (providing waterproofing, elasticity, and temperature resistance) with robust reinforcement fabrics (offering tensile strength and puncture resistance ) means the entire system is designed to effectively manage multiple, simultaneous stresses—such as thermal cycling, building movement, foot traffic, and impacts—that would compromise a roof made from a single material or a less integrated system. This systemic design ensures a level of resilience and durability greater than the sum of its individual parts, leading to a more reliable, longer-lasting, and protective roofing solution that minimizes future repair needs and provides peace of mind for the building owner.

3. Types of Modified Bitumen Roofing Systems: APP vs. SBS

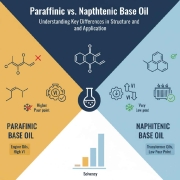

The selection between the two primary types of modified bitumen—Atactic Polypropylene (APP) and Styrene-Butadiene-Styrene (SBS)—is a critical decision, as each possesses distinct characteristics tailored to specific environmental conditions and performance requirements. Both types are polymer-modified, yet their differing chemical structures result in unique advantages for various applications.

APP (Atactic Polypropylene) Modified Bitumen

APP is a “plastic-like” thermoplastic polymer that integrates into the bitumen to form a uniform matrix. This modification yields a material with a higher softening point, providing excellent stability at elevated temperatures. It is known for its inherent UV and weathering resistance, making it a highly durable compound. APP membranes are often characterized by a plastic-like appearance and enhanced UV protection, which significantly contribute to their effectiveness and longevity.

Due to its superior UV resistance and high-temperature stability, APP modified bitumen is typically recommended for warmer, more southern climates with extensive sun exposure. It excels at resisting ultraviolet rays and efficiently shedding water from the roof surface, thereby extending the roof’s lifespan in sunny regions.

APP membranes are predominantly installed using heat-welded or torch-applied methods. This process involves heating the material’s underside with a torch to soften or melt it, which then forms a strong, monolithic, and water-resistant bond upon cooling.

SBS (Styrene-Butadiene-Styrene) Modified Bitumen

SBS is a “rubber-like” thermoplastic elastomer that provides superior flexibility, elasticity, and “compound memory”—the ability to stretch and recover its original shape, much like rubber. This “rubberized asphalt” enables the modified bitumen to expand and contract significantly with temperature fluctuations without cracking or splitting, making it highly resistant to thermal cycling. It also offers enhanced low-temperature flexibility, ensuring it remains pliable and functional in cold conditions.

SBS is particularly well-suited for colder, more northern climates due to its enhanced low-temperature flexibility and its ability to withstand freeze-thaw cycles. Its superior elongation and recovery properties make it exceptionally durable and applicable in situations where there may be significant movement or deflection of the underlying deck, or in areas prone to hail.

SBS membranes offer greater versatility in installation methods. While they can be installed by torch application, they are also commonly applied using cold adhesive methods, hot asphalt mopping, or through the use of self-adhering (SA) sheets.

The clear distinction in suitability for “southern climates” (emphasizing UV resistance and higher softening point for APP) versus “northern climates” (highlighting low-temperature flexibility and elasticity for freeze-thaw cycles for SBS) is more than a mere preference; it signifies a critical optimization strategy. Selecting the incorrect type of modified bitumen for a given climate can lead to premature roof failure—for example, APP becoming brittle and cracking in extreme cold, or SBS degrading faster under intense, prolonged UV exposure if not adequately surfaced. This direct relationship between prevailing climate conditions and the optimal modified bitumen material selection directly impacts the long-term performance and durability of the roofing system. This underscores the importance of expert consultation in material selection, as the most effective modified bitumen solution is not universal but highly dependent on specific climatic factors, allowing for tailored, climate-specific solutions.

Furthermore, the difference in application versatility between APP and SBS is a direct consequence of their inherent material properties. APP’s “plastic-like” nature and higher softening point make it ideal for heat welding, enabling it to form a strong, monolithic bond through melting. In contrast, SBS’s “rubber-like” flexibility and lower melting point allow for a wider range of application methods, particularly those that avoid open flames, such as cold-applied or self-adhered systems. These flame-free methods offer benefits in terms of safety, speed, and suitability for occupied buildings (due to low odor ) or projects with fire restrictions. This demonstrates that the material’s properties dictate the viable application methods, and these methods, in turn, influence installation safety, project timelines, and overall suitability for different building environments and operational constraints. This connection between material science and practical installation considerations highlights the need for a knowledgeable contractor who understands these nuanced relationships to recommend the most appropriate system and application method for a given project.

APP vs. SBS Modified Bitumen: A Comparative Overview

Modified bitumen roofing systems are highly regarded for their versatility and robust performance, making them an optimal choice for a broad spectrum of applications, especially where flat or low-slope roofing is a requirement. Their unique composition allows them to perform exceptionally well in diverse environments, consistently providing reliable waterproofing and long-term protection.

Primary Use: Low-Slope and Flat Roofs

Modified bitumen is specifically designed and demonstrates exceptional effectiveness for commercial, industrial, and certain residential buildings featuring flat or low-slope roofs. This is the primary domain where its superior waterproofing capabilities, inherent flexibility, and impressive durability are most evident, offering robust weather protection and significantly extending the roof’s lifespan. While some sources mention suitability for “steep-slope roofs” , the overwhelming majority of information consistently emphasizes low-slope or flat applications as its primary and most effective use.

Diverse Building Types

The proven performance and adaptability of modified bitumen make it a preferred choice for a variety of critical structures and building types that demand dependable low-slope roofing solutions. These include:

- Hospitals

- Schools

- Hotels

- Sporting Arenas

- General commercial buildings

- Industrial facilities

Beyond Roofing: Comprehensive Waterproofing

The inherent waterproofing and adhesive properties of modified bitumen, particularly its capacity to form a robust barrier, extend its utility beyond just roof surfaces. It is frequently utilized for:

- Waterproofing foundations, providing a robust barrier against moisture infiltration and protecting below-grade structures.

- Waterproofing car park decks and bridge decks, where its durability and resistance to traffic, thermal cycling, and environmental elements are crucial for long-term structural integrity.

- Green roofs, where its robust, multi-layered waterproofing system can reliably withstand the demands of vegetative layers, continuous moisture retention, and root penetration.

- Road construction and paving mixtures, particularly SBS-modified bitumen, due to its enhanced flexibility, durability, and improved skid resistance, which contribute to safer and smoother driving surfaces.

The successful application of modified bitumen in complex scenarios like green roofs or car park decks implies more than basic waterproofing. These applications involve significant loads, potential for continuous moisture, root intrusion, and complex interfaces with other building components. The effectiveness of modified bitumen in these demanding areas is a testament to its multi-layered design and the synergy of its components. It functions not merely as a standalone membrane but as an integral part of a robust waterproofing system capable of handling complex environmental and structural demands, demonstrating its engineered resilience beyond simple surface protection. This positions modified bitumen as a solution for intricate engineering challenges, elevating its perception from a basic roofing material to a high-performance system capable of integrating into sophisticated and multi-functional building designs, which appeals to architects and developers seeking advanced, reliable solutions.

Re-roofing Compatibility

SBS-modified roofing membranes generally exhibit compatibility with existing asphalt products. This characteristic makes them a practical and efficient option for re-roofing projects over existing asphaltic systems, often allowing for a single-layer overlay to extend the system’s longevity.

5. The Pros and Cons: A Balanced View of Modified Bitumen Roofing

As with any significant investment in property infrastructure, selecting a roofing system necessitates a comprehensive understanding of its advantages and potential drawbacks. Modified bitumen roofing offers a compelling array of benefits that make it a preferred choice for many, yet it also presents considerations that warrant careful evaluation to ensure alignment with specific project requirements and expectations.

Advantages

- Exceptional Durability and Longevity: Modified bitumen roofs are engineered for high durability, designed to withstand extreme weather conditions, including intense heat, heavy snowfall, ice, and freeze-thaw processes. With proper installation and consistent maintenance, these roofs can typically last between 15 to 30 years, with many sources indicating an average lifespan of 20-25 years. This impressive longevity is largely attributed to its multi-ply, thick design, which provides enhanced resistance to punctures, and the flexibility imparted by polymer additives. They also exhibit high resistance to wear and tear and can accommodate foot traffic better than some other flat roofing options, making them suitable for accessible roof areas.

- Superior Waterproofing Capabilities: A distinguishing feature of modified bitumen roofing systems is their excellent waterproofing performance. When installed as multi-ply systems, these roofs form a robust, seamless barrier against leaks. The application methods, particularly torch-applied systems where seams are melted together, ensure a strong, water-resistant seal that effectively prevents water infiltration and protects the building interior from moisture damage.

- Enhanced Energy Efficiency: Many modified bitumen roofs can be designed with reflective surfaces or have reflective coatings applied to them, often in white or light colors. These coatings reflect sunlight, significantly reducing heat absorption and helping to maintain cooler indoor temperatures, particularly in hot climates. This can translate into lower cooling costs and improved energy efficiency for the building. Proper insulation installed beneath the membrane further amplifies these energy-saving benefits.

- Flexibility and Adaptability to Building Movement: The polymer additives, especially SBS, imbue the membrane with elastic properties, allowing it to stretch and recover. This flexibility enables the roof to expand and contract without cracking or splitting in response to temperature fluctuations and the natural movements of the building or underlying deck. This adaptability is crucial for long-term performance and resistance to stress-induced damage, making it ideal for areas experiencing extreme weather variations.

- Resistance to Fire, Wind, and Hail: Modified bitumen roofs are rated for resistance against fire, wind, and hail. Their sturdy composition provides superior performance against gusty winds, offering improved defense against potential uplift or roof deck damage. They possess a resilient composition capable of absorbing the impact of small to medium-sized hailstones without cracking or breaking. Furthermore, their asphalt content contributes to fire-resistant properties, helping to impede the spread of flames.

- Ease of Installation and Repair: Modified bitumen roofing systems are relatively straightforward to install compared to some other complex roofing materials, which can contribute to reduced installation time and labor costs. When repairs become necessary, issues can often be addressed efficiently with patching damaged sections. This is a simple and cost-effective solution that ensures a swift return to functionality.

- Environmental Considerations: Many manufacturers incorporate recycled materials into the production of modified bitumen, aligning with sustainability efforts. The extended lifespan of these roofs minimizes the need for frequent replacements, thereby reducing construction waste. Additionally, modified bitumen materials can often be recycled at the end of their service life, further diminishing their environmental footprint.

- Sound Dampening: While not its primary function, the multi-layered, thick composition of modified bitumen can provide a quieter and more comfortable indoor environment compared to metal roofing, particularly during rain or hailstorms.

Disadvantages

- Potential for Heat Absorption: Standard, dark-colored modified bitumen roofs, typically black, naturally attract and absorb a significant amount of sunlight, retaining heat during summer months. This can lead to higher indoor temperatures and potentially increased cooling expenses if reflective coatings or lighter-colored variants are not applied.

- Installation Risks (Torch-Applied): The torch-applied method, while highly effective for creating a watertight seal, involves an open flame and carries a fire risk if not performed by highly trained and experienced professionals adhering to strict safety protocols. Overheating the compound during installation can also lead to material breakdown and flammability.

- Lifespan Shorter Than Some Alternatives: While durable, modified bitumen typically lasts 15-30 years. This lifespan can be shorter compared to some other premium roofing materials like metal (which can last 50+ years), tile, or certain EPDM systems (up to 50 years). However, it generally offers a longer lifespan than traditional asphalt roll roofing.

- Vulnerability to Ponding Water: Modified bitumen roofs, being flat or low-slope, are susceptible to damage from water ponding if drainage is inadequate. If pooling water remains on the roof for an extended period, it can seep into seams or minor cracks over time, leading to leaks and potential structural degradation. Therefore, adequate drainage design and diligent maintenance are vital.

- Initial Cost: The upfront cost of installing a new modified bitumen roof can sometimes be higher than other flat roof membranes like TPO or traditional built-up roofing (BUR). However, its enduring durability, minimal maintenance requirements, and energy efficiency can often offset these initial expenses over the long term, making it a cost-effective choice over the roof’s lifecycle.

- Limited to Low-Slope Applications: Modified bitumen roofing is specifically designed for and performs optimally on flat or low-slope roofs (typically pitches between ¼:12 to 1:12). It cannot be installed on steep-sloped roofs, which limits its applicability to certain architectural designs and property types.

- Requires Regular Maintenance: Despite its inherent durability, modified bitumen roofs require regular maintenance, including routine inspections, cleaning, and prompt minor repairs, to prolong their lifespan and ensure optimal performance. Neglecting maintenance can result in the need for more frequent and costly repairs or premature roof failure.

The discussion of cost often presents a dual perspective: a potentially higher initial investment compared to some alternatives , but significant long-term savings through reduced maintenance, energy efficiency, and fewer replacements. This immediately suggests that the total cost of ownership (TCO) is the critical metric for evaluation, rather than solely the upfront expense. The higher initial investment in modified bitumen is frequently offset by its extended durability, energy savings, and ease of repair, ultimately leading to a superior return on investment over the roof’s entire lifespan. This framing positions modified bitumen as a smart, strategic, long-term investment, appealing to clients who prioritize operational costs, asset management, and lifecycle value over merely the lowest procurement price.

It is also important to note that many of the perceived “disadvantages” of modified bitumen are not inherent, unmitigable flaws of the material itself, but rather risks associated with improper selection, installation, or maintenance. For example, “heat absorption” can be effectively managed by applying reflective coatings or choosing lighter-colored variants. The “installation risks” of the torch-down method can be entirely circumvented by opting for safer self-adhered or cold-applied methods. “Vulnerability to ponding water” is primarily a design and drainage issue, not an intrinsic material defect. Even a “shorter lifespan” is frequently qualified by the necessity of “proper maintenance”. This pattern implies that the potential drawbacks of modified bitumen can largely be managed or eliminated through informed decision-making and professional execution. This shifts the narrative from “modified bitumen has flaws” to “modified bitumen requires expert handling to maximize its benefits and mitigate potential issues,” reinforcing the critical need for a reputable, experienced contractor who can provide tailored recommendations, ensure flawless installation, and offer comprehensive maintenance plans.

Key Advantages and Disadvantages of Modified Bitumen Roofing

| Category | Advantages | Disadvantages |

|---|---|---|

| Performance | Exceptional Durability & Longevity (15-30 years) | Potential Heat Absorption (without coating) |

| Superior Waterproofing Protection | Vulnerability to Ponding Water (if drainage inadequate) | |

| Flexibility & Adaptability to Building Movement | Lifespan shorter than some alternatives (e.g., metal, EPDM) | |

| Resistance to Fire, Wind, and Hail | Limited to low-slope applications | |

| Cost & Efficiency | Enhanced Energy Efficiency (with reflective coatings) | Higher Initial Cost (compared to some options) |

| Long-Term Cost-Effectiveness (due to durability, low maintenance) | ||

| Installation & Maintenance | Ease of Installation and Repair | Installation Risks (torch-applied, requires expertise) |

| Minimal Maintenance (with regular upkeep) | Requires Regular Maintenance for longevity | |

| Other | Environmental Considerations (recyclable, recycled content) | |

| Sound Dampening |

6. Mastering the Installation: Methods and Best Practices

The successful performance, long-term durability, and warranty validity of a modified bitumen roof depend profoundly on its proper installation. Modified bitumen systems are typically multi-layered, and various application methods are employed, each with its own benefits, safety considerations, and suitability for specific project conditions.

Overview of System Layers

A modified bitumen roof system is a meticulously engineered composite structure, comprising several interdependent layers that collectively contribute to its overall strength, insulation, and waterproofing capabilities. These layers are applied directly to the roof deck, forming a cohesive and robust barrier.

- Insulation: This foundational layer is applied first and is particularly crucial in colder climates to retain heat within the building and improve its overall energy efficiency. Insulation can be mechanically attached with screws and plates or fully adhered with glue or a hot mop, depending on the deck type and desired performance level.

- Vapor Barrier: Positioned on top of the insulation, this underlayment helps to control moisture within the roof system by minimizing the passage of water vapor. This prevents condensation and potential moisture issues that could compromise the roof’s integrity or lead to mold growth.

- Overlay Board/Cover Board: Installed next, this layer provides a smooth, monolithic, and stable support surface for the subsequent modified bitumen membranes. Precision in its application is crucial to ensure a level surface and prevent “ponding,” which occurs when the roof is not level and collects water, potentially leading to leaks.

- Base Sheet: This is the first layer of modified bitumen membrane, serving as the foundation for the primary waterproofing system. It may be secured to the overlay board by direct heat fusing, hot mopping, or with adhesive.

- Modified Bitumen Membrane (Ply Sheets): These are additional layers of reinforced fabric, composed of asphalt, polymers (APP or SBS), and fillers, which form the primary waterproofing element of the system. In multi-ply systems, these layers are strategically applied to build up thickness and enhance resistance.

- Cap Sheet: The top membrane layer serves as the final protective surface. It can be smooth or embedded with mineral granules (granulated surface) to provide protection against UV radiation, mechanical damage, and enhance aesthetic appeal. In a two-layer system, this is the final rolled layer; in a three-layer system, a granulated cap sheet is applied over a smooth cap sheet.

- Flashing for Penetrations: Self-adhering modified bitumen membranes are typically used as flashing around features that penetrate the roof, such as vents, pipes, or HVAC units, providing a watertight seal. This is often supplemented by metal flashing, which is primed before the base sheet is affixed to ensure proper adhesion.

7. Frequently Asked Questions (FAQs) About Modified Bitumen Roofing

What is the typical lifespan of modified bitumen roofing?

The average lifespan of a modified bitumen roof is approximately 15 to 30 years, with many sources indicating 20-25 years, provided it receives proper upkeep and maintenance. Factors such as the quality of installation, local climate conditions, level of foot traffic, and material quality significantly influence its longevity.

What are the common application methods for modified bitumen roofing?

Modified bitumen is commonly applied through heat welding (torch-applied), mopping in hot asphalt, cold-process adhesive, or as self-adhering membranes. Some membranes can also be mechanically attached. The choice of method often depends on the type of modifier (APP or SBS), climate, and project-specific safety considerations.

How can modified bitumen roofing be repaired?

Typically, damaged sections of modified bitumen roofing are repaired by removing the affected membrane, applying a modified bitumen patch, and then sealing it to ensure protection. This process is generally straightforward and cost-effective. Regular inspections help identify minor damages early, preventing them from escalating into major problems.

What advantages do self-adhered membranes offer?

Self-adhered modified bitumen is notably simpler and quicker to install due to the pre-applied adhesive layer. Additionally, it significantly reduces any fire hazards linked with open-flame torching, making it a safer option for many projects.

What is cold-applied roofing?

Cold-applied roofing refers to membranes that feature a sanded or similar aggregate bottom and rely on hot asphalt or cold-applied adhesives for bonding, rather than heat from a torch. This method eliminates the need for an open flame during installation.

Is modified bitumen roofing environmentally friendly?

Many modified bitumen roofing materials are produced using recycled content, contributing to sustainability efforts. Their long lifespan reduces the frequency of replacements, thereby minimizing construction waste. Furthermore, modified bitumen materials can often be recycled at the end of their service life, further diminishing their environmental impact.

How does modified bitumen compare to traditional built-up roofing (BUR)?

Modified bitumen roofing is considered a modern evolution of BUR. While both are asphalt-based and multi-layered, modified bitumen incorporates polymers for enhanced flexibility, durability, and temperature resistance. It is generally lighter and easier to install than BUR, and offers superior flexibility and thermal resistance.

Can modified bitumen roofs be installed on steep slopes?

Modified bitumen roofing systems are primarily designed for and perform best on flat or low-slope roofs (typically pitches between ¼:12 to 1:12). They are generally not recommended for steep-sloped roofs.

Modified bitumen (Mod-bit) offers a durable, flexible, and waterproof solution for flat and low-slope roofs. This advanced material excels in various weather conditions, resisting UV and temperature changes. Selecting between APP and SBS Mod-bit depends on your climate: APP is best for warm, sunny areas, while SBS suits colder regions with extreme temperature shifts. This ensures top performance.

Though Mod-bit may have a higher upfront cost, its long lifespan, energy efficiency, and low maintenance reduce overall expenses. Potential issues can be mitigated by choosing the right material and having it professionally installed.

Ultimately, Mod-bit is a reliable, high-performance option for durable, energy-efficient roofs. Always pick an experienced contractor to maximize its benefits.

I’m choosing between TPO and Modified Bitumen for a new commercial building. The article mentions mod-bit’s TCO (Total Cost of Ownership) is good. What specifically makes it a better long-term investment than TPO?

While TPO often has a lower initial cost, Modified Bitumen offers better puncture resistance and a thicker, multi-ply design, which translates to higher durability and typically a longer service life (15-30 years). Its superior elasticity (SBS) makes it far better at accommodating building movement and thermal cycling, minimizing long-term repair costs compared to single-ply systems.