Introduction to Types of Lub Cuts and Their Applications

Lubricant cut, also known as lube oil stock or lube base stock, is a crucial and fundamental component in the petroleum industry. Derived from crude oil refining, it primarily consists of hydrocarbons with carbon chain lengths ranging from 20 to 50 carbon atoms. The significance of lube cut in the lubrication industry is such that it constitutes approximately 85 to 95 percent of the final structure of lubricating oils. This feedstock is sourced from crude oil refineries and undergoes complex refining processes in lube oil refineries to become base oil, the main ingredient in the production of motor oils, industrial oils, and greases.

Base oils derived from lube cuts play a vital role in reducing friction and preventing wear on moving metal parts in various machinery and engines. The use of these lubricants not only extends the service life of equipment but also significantly reduces maintenance costs. Today, expectations for lubricating oils go beyond mere friction reduction and include aspects such as improved energy efficiency, protection against corrosion and wear, and resistance to rust. This indicates an increasing demand for higher quality lube cuts and more complex related refining processes.

This article will attempt to provide a comprehensive understanding of the nature, applications, production process, grade types, factors affecting quality, its relationship with other petroleum products, and its commercial aspects in the Iranian market through a thorough examination of lube cuts.

Lub Cut Production Process:

The production of lube cut is a multi-stage and precise process that begins with the refining of crude oil as the feedstock. The initial refining aims to remove impurities and undesirable materials from the crude oil. In this stage, the crude oil is heated and vaporized, then separated into various fractions based on different boiling points in an atmospheric distillation tower. Lighter fractions are converted into gasoline and other fuels, while heavier fractions are used for the production of base oils. This initial separation is a crucial step that lays the groundwork for subsequent refining processes.

The residue from atmospheric distillation, containing heavy hydrocarbons, is transferred to a vacuum distillation unit (VDU) for further processing. Vacuum distillation is performed under very low pressure (10-40 mmHg) to lower the boiling point of heavy oils and prevent their thermal cracking, which occurs at higher temperatures under atmospheric pressure (above 370-380 °C). The vacuum distillation unit separates various gas oils and a heavy residue. Lub cut is typically obtained as one of the side products from the vacuum distillation tower. This stage of distillation is specifically designed to process the heaviest fractions of crude oil to produce lube cut without degrading its molecular structure.

The lube cut fraction obtained from vacuum distillation still requires further refining to improve its properties. This refining includes improving viscosity, temperature stability, oxidation resistance, and color, as well as removing undesirable compounds such as aromatics, sulfur, and wax. Two main types of refining processes are used for lube cut: extraction and conversion.

In the solvent extraction process, which is a separation method, solvents such as furfural, phenol, or N-methylpyrrolidone (NMP) are used to remove aromatic compounds. Aromatic compounds are not suitable for lubrication purposes due to their low oxidation stability and low viscosity index. The aromatic extract resulting from this process is a byproduct used in the production of industrial carbon black. The lube cut remaining after the removal of aromatics, now called raffinate, has better properties for use as base oil. The selection of the appropriate solvent and the efficiency of the extraction process play a significant role in determining the final quality of the lube cut.

The raffinate from the previous stage then undergoes a dewaxing process. This process is typically carried out using solvents such as methyl ethyl ketone (MEK) and toluene to remove paraffin waxes, which have a high pour point and can cause the oil to solidify at low temperatures. The byproduct of this process is paraffin wax (slack wax). Dewaxing is essential to ensure the oil maintains its fluidity and lubricating properties over a wide range of operating temperatures, especially in cold environments.

The final stage of refining usually involves hydrofinishing or hydrotreating. In this stage, the dewaxed oil reacts with hydrogen in the presence of a catalyst at high temperatures and pressures to remove polar compounds containing sulfur, nitrogen, and oxygen, and to saturate any remaining unsaturated molecules. This process improves the color and chemical stability of the oil. Hydrofinishing is a critical step in achieving high-quality base oils with excellent resistance to degradation.

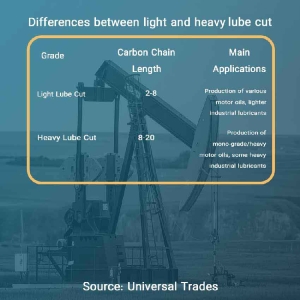

Types of Lub Cut Grades and Their Applications:

Lub cut is generally divided into two main grades: light lube cut and heavy lube cut. These two grades differ in viscosity and, consequently, find different applications in the oil industry.

Light Lub Cut:

Light lube cut has a lower viscosity. This grade is mainly used for the production of various types of motor oils. It is also used in the production of lighter grade lubricants and industrial oils. The widespread use of light lube cut in the production of a wide range of motor oils indicates that this grade acts as a versatile feedstock in the lubrication industry. Its lower viscosity allows it to be used in the production of base oils that require good flow characteristics.

Heavy Lub Cut:

In contrast, heavy lube cut has a higher viscosity. This grade is specifically used for the production of mono-grade motor oils (with a heavy grade), especially for diesel engines and gearboxes. It may also be used in some industrial applications that require high viscosity lubricants. The specific application of heavy lube cut in heavy-duty and mono-grade motor oils indicates its suitability for conditions requiring high viscosity and strong lubrication under high loads and temperatures.

Key Factors Affecting Lub Cut Quality:

The quality of lube cut depends on several factors involved in the various stages of production and refining. Understanding these factors is crucial for producing lube cut with desired properties suitable for intended applications.

Source and Composition of Crude Oil:

This is one of the most important factors determining the quality of lube cut. Not all crude oils are suitable for producing high-quality lube cut. Factors such as the chemical composition of the crude oil, the percentage of the desired lube cut fraction in the crude oil, and the presence of impurities significantly affect the quality and yield of lube cut. The type of hydrocarbon molecules present in the crude oil (paraffinic, naphthenic, aromatic) also affects the properties of the final lube cut. Therefore, selecting the appropriate oil feedstock is the first and most fundamental step in determining the potential quality of the lube cut.

Presence of Impurities:

Impurities in the lube cut can significantly reduce its quality for lubrication purposes. The efficiency of removing impurities (aromatics, waxes, sulfur, nitrogen) during refining is crucial for achieving the desired quality of the lube cut. Modern conversion processes such as hydrocracking and hydrotreating generally produce higher quality base oils with lower aromatic content and better stability. Therefore, the selection and optimization of refining technologies are essential for adjusting the properties of the lube cut to meet specific performance requirements.

Relationship of Lub Cut with Other Petroleum Products:

As one of the products of crude oil refining, lube cut has a close relationship with other petroleum products. This relationship can be observed in both the upstream and downstream stages of the oil refining process. In the upstream stages, lube cut is directly obtained from crude oil refining. The characteristics of the crude oil used largely determine the yield and quality of the lube cut.

In the downstream stages, lube cut is used as the primary feedstock for the production of base oils. Base oils are the essential components of most lubricants and typically constitute 80 to 99 percent of the final formulation. These base oils are classified into different groups (Group I, II, III mineral oils, Group IV polyalphaolefins, Group V others) based on their level of refining and properties. The quality of the lube cut directly affects the potential quality of the base oils derived from it.

Base oils are then blended with various additives to produce final motor oils and industrial lubricants such as engine oils, gear oils, hydraulic fluids, and industrial lubricants. Light lube cut is used for the production of various types of motor oils, while heavy lube cut is used for heavy-duty motor oils.

In addition, other byproducts are produced during the refining of lubricating oils from lube cut. Slack wax is one such product, obtained during the dewaxing process. Slack wax is a mixture of wax and oil and is used in the production of paraffin wax and other industrial applications. Furfural extract is also a byproduct of the solvent extraction unit, rich in aromatic compounds, and is used as a feedstock in the production of industrial carbon black, especially in the rubber industry.

Compared to other petroleum fractions, lube cut falls within a specific range of boiling points that makes it suitable for the production of lubricants. Lighter fractions such as LPG, naphtha, kerosene, and gas oil are mainly used as fuel or feedstock for petrochemical industries. Vacuum bottom or vacuum distillation residue is the heaviest petroleum fraction remaining after vacuum distillation. This material can be converted into bitumen (asphalt) through thermal processes such as thermal cracking or coking.

Trade of Lub Cut:

The price of lube cut is influenced by various factors. Global crude oil prices and benchmark prices published by Platts for the Persian Gulf region are among the important factors. The average price of high-sulfur fuel oil (HSFO) is also considered in calculating the value of lube cut. Fluctuations in crude oil prices directly affect the cost of producing and processing lube cut. Government regulations and pricing policies can also affect the price of lube cut in the domestic market. The exchange rate (such as the NIMA rate in Iran) also plays a significant role in determining the price of lube cut. These factors indicate that the price of lube cut is complexly influenced by multiple factors in the global oil market, regional fuel prices, domestic regulations, and exchange rates.

Standards and Specifications of Lub Cut:

The Iran Mercantile Exchange plays an important role in standardizing accepted goods, including lube cut. National standards for lube cut, iron ore, and molybdenum concentrate have been developed with a focus on the Mercantile Exchange. One text refers to multi-grade motor oil produced using paraffinic base oil (derived from lube cut) that complies with API SG/CD and ISIRI 3785 standards. The development and implementation of national standards for lube cut are of great importance in facilitating trade and increasing consumer confidence in the Iranian market. The quality and grade of the final lubricants produced are directly affected by the quality and grade of the lube cut used. Therefore, compliance with lube cut standards is essential for maintaining the overall quality of the lubrication industry’s products.

Conclusion:

Lub cut, as the primary feedstock in the production of base oils and, consequently, various lubricants, plays a vital role in the oil industry and the country’s economy. Its production process involves complex stages of crude oil refining, atmospheric and vacuum distillation, and then secondary refining processes such as solvent extraction, dewaxing, and hydrotreating or conversion processes. Different types of lube cuts, especially light and heavy grades, have different applications in the production of motor and industrial oils. The quality of lube cut is strongly influenced by factors such as the source and composition of crude oil, the refining technologies used, and the amount of impurities present. Lub cut not only has a direct relationship with base oils and final lubricants, but valuable byproducts such as slack wax and furfural extract are also produced during its refining process. The trade of lube cut in Iran is conducted through the Mercantile Exchange, and its price is influenced by multiple factors, including global oil prices, exchange rates, and domestic regulations. The existence of specific standards for lube cut helps ensure quality and facilitate the trade of this important feedstock.

What are the stages involved in the production process of Lube Cut, and why is Vacuum Distillation (VDU) considered a crucial step in this process?

The production process of Lube Cut is a multi-stage and precise operation that begins with crude oil refining. Its main stages include:

Primary Refining and Atmospheric Distillation: Crude oil is heated and vaporized. Then, in the atmospheric distillation tower, it is separated into various cuts based on different boiling points. Lighter cuts (like gasoline) are removed, while heavier cuts are used for producing base oils.

Vacuum Distillation (VDU): The residue from atmospheric distillation, which contains heavy hydrocarbons, is transferred to the vacuum distillation unit. This stage is crucial because it is performed under very low pressure (10-40 mmHg) to lower the boiling point of heavy oils and prevent their thermal decomposition (which would occur at higher temperatures under atmospheric pressure). Lube cut is typically obtained as one of the by-products from this vacuum distillation tower.

Further Refining Processes: The lube cut obtained from vacuum distillation still requires further refining to improve its properties. This includes:

Solvent Extraction: Performed using solvents like furfural to remove aromatic compounds (which have low oxidation stability).

Dewaxing: Carried out using solvents such as methyl ethyl ketone (MEK) to remove paraffinic waxes (which can cause the oil to solidify at low temperatures).

Hydrofinishing or Hydrotreating: In this stage, the dewaxed oil reacts with hydrogen in the presence of a catalyst to remove polar compounds containing sulfur, nitrogen, and oxygen, thereby improving the oil’s color and chemical stability.