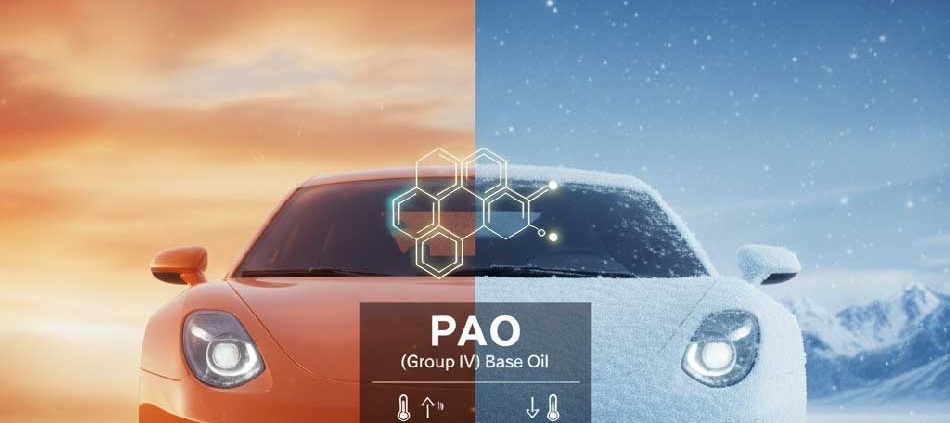

Group IV Base Oil (PAO): The Optimal Choice for Extreme High and Low Temperatures

The world of lubricants is divided into five groups (I to V) based on API standards. Group IV, which consists of Polyalphaolefins (PAO), is recognized as the true representative of synthetic base oils. Unlike mineral oils derived directly from crude oil refining, PAO is chemically synthesized from ethylene molecules. This controlled process creates molecules with a uniform, impurity-free structure, ensuring performance under the harshest conditions.

2. PAO Performance Advantages: Beyond Temperature Tolerance

The clean and regular structure of PAO provides numerous benefits for the final lubricant, making it ideal for specialized applications:

- Extremely High Viscosity Index (VI): This property signifies excellent resistance to viscosity changes during temperature fluctuations. PAO maintains its viscosity at high temperatures and avoids excessive thickening at low temperatures.

- Extraordinarily Low Pour Point: PAO can maintain its fluidity even at very low temperatures (down to $ -60^{\circ}\text{C}$), making it essential for frigid climates or cryogenic applications.

- Superior Thermal and Oxidation Stability: High resistance to decomposition at high operating temperatures leads to longer oil life and reduced formation of sludge and deposits.

- Low Volatility: Minimized evaporation at high temperatures reduces oil consumption and vapor pollutants.

3. Introducing PAO Grades and Specialized Applications

PAO base oils are classified based on their Kinematic Viscosity at (in centistokes or cSt). Each grade has its specific applications in final formulation:

4. Key Applications in Specialized Industries

Due to its unique characteristics, PAO is used not only in premium engine oils but also extensively in the following critical industries:

- Aerospace Industry: For lubricating jet engines and flight control systems that must maintain stable performance across extreme temperature ranges, from high altitudes to ground level.

- Refrigeration Compressors: In refrigeration and chiller systems where fluidity at extremely low temperatures is vital to prevent operational failure.

- Sensitive Industrial Equipment Lubrication: In air compressors (especially screw compressors) and vacuum pumps that experience high operating temperatures.

5. Cost Considerations and Conclusion

It is true that PAO (Group IV) base oil has a higher price than Group I, and Group II, and even Group III due to its complex manufacturing process. However, this higher price is often offset by significantly longer oil life, reduced energy consumption, and better protection of expensive equipment. Choosing PAO is an investment that guarantees high-performance returns in severe operating conditions.

What is the main difference between Group IV (PAO) base oil and mineral base oils (Groups I & II), and why is it called “True Synthetic”?

The key difference lies in the manufacturing process. Mineral base oils are derived directly from the physical refining and distillation of crude oil. In contrast, PAO (Group IV) is produced via a controlled chemical synthesis using ethylene molecules. This chemical synthesis creates a uniform, pure molecular structure free of wax or sulfur impurities, resulting in an extremely high Viscosity Index (VI) and superior thermal stability.

Given the higher cost of PAO compared to mineral oils, how is its use in specialized industries justified?

The higher cost is justified by longer oil life (excellent thermal and oxidation stability), reduced oil consumption (low volatility), and superior protection for expensive equipment operating under severe conditions.