Group 2 Base Oils: properties, Grades, and Applications

Base oils are the fundamental components of lubricants, crucial for the efficient and prolonged operation of machinery across virtually all industrial and automotive sectors. These oils dictate a lubricant’s performance characteristics and behavior under various operating conditions, including extreme temperatures and pressures. Their inherent properties—such as viscosity, thermal stability, and oxidation resistance—are then enhanced and customized for specific applications through the precise addition of various additive packages, which impart vital capabilities like improved lubrication, detergency, anti-wear properties, and thermal stability to the final product.

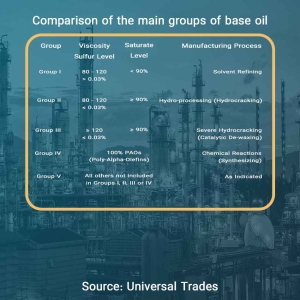

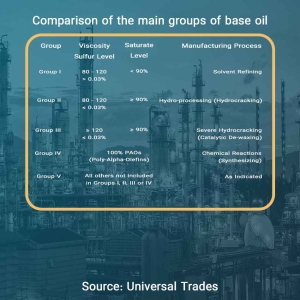

The American Petroleum Institute (API) has established a comprehensive classification system to standardize base oil categorization based on their refining methods and intrinsic properties. This widely recognized system divides base oils into five main groups (Groups I, II, III, IV, and V), providing a common framework that facilitates communication and selection for both manufacturers and consumers in the global lubricant market.

Group 2 base oils, as defined by the API, possess specific chemical and physical parameters that set them apart from other groups. They are characterized by:

- Over 90% saturated compounds

- Less than 0.03% sulfur content

- A Viscosity Index (VI) between 80 and 120 (though typically achieving over 100)

This classification reflects a critical threshold in purity and performance, profoundly impacting lubricant technology. The stringent requirements for saturated compounds and low sulfur content are direct outcomes of advanced refining processes. High saturation improves the oil’s intrinsic resistance to degradation by reducing reactive carbon-carbon double bonds, while low sulfur content minimizes corrosive acid and sludge formation, extending lubricant lifespan and enhancing environmental profiles. A VI consistently above 100 demonstrates superior viscosity stability across a broader temperature range. This combination of purity and improved viscosity characteristics makes Group 2 oils essential for modern lubricants, enabling them to meet performance and environmental demands that Group I oils often cannot.

1. API Base Oil Classification Summary

Below is a summary of the API base oil classification system, highlighting the defining characteristics of each group.

2. Production and Refining of Group 2 Base Oils

The evolution from Group I to Group III base oils fundamentally reflects the continuous advancement in petroleum refining technology over the past 70 to 80 years. This journey has progressed from simpler, less intensive solvent refining methods to more complex and severe hydroprocessing techniques, driven by the demand for higher purity and performance in lubricants.

The production of Group 2 base oils represents a significant shift from traditional Group I manufacturing, primarily achieved through the implementation of advanced hydroprocessing techniques. This multi-stage process is designed to yield a purer, more stable base oil.

-

Hydrocracking: This advanced method is the cornerstone of Group II base oil production, replacing less effective solvent refining. Hydrocracking involves subjecting crude oil fractions (typically VGO) to severe conditions: high pressure (typically 1500-3000 psi) and high temperature (around 350-400°C) in the presence of specialized metallic catalysts (e.g., nickel-molybdenum or cobalt-molybdenum).

- Primary objectives: Break down larger, more complex hydrocarbon molecules into smaller, more stable saturated ones; saturate carbon-carbon double bonds (which are reactive and prone to oxidation); open aromatic rings and convert them into more stable paraffinic structures; and remove impurities like sulfur (converted to hydrogen sulfide) and nitrogen (converted to ammonia).

- Impact: This process dramatically enhances the oil’s viscosity index, oxidation stability, and overall purity.

-

Hydrotreating: Following hydrocracking, the base oil undergoes further hydrotreating. This stage uses hydrogen under high temperature and pressure to remove any remaining impurities, especially sulfur and nitrogen compounds. Hydrotreating is crucial for further increasing the oil’s oxidation stability, improving its color, and reducing its reactivity.

-

Catalytic Dewaxing: To ensure excellent low-temperature performance and a low pour point, catalytic dewaxing is employed. Unlike older solvent dewaxing methods, this process chemically alters straight-chain paraffins (which tend to solidify at lower temperatures) into branched isoparaffins. A catalyst, often containing zeolite, selectively reshapes the paraffinic molecules, which not only lowers the pour point but also maintains or even improves the viscosity index.

-

Filtration: The final step involves filtration to remove any residual moisture and particulates, ensuring the ultimate purity and clarity of the Group 2 base oil.

The fundamental difference in Group I and Group II base oil production lies in the efficiency of impurity removal. Historically, Group I base oils were produced primarily through solvent refining. This simpler process involved atmospheric and vacuum distillation, followed by solvent extraction (to remove undesirable aromatic and polar compounds) and a mild hydrofinishing step. Solvent refining is less efficient at removing sulfur, nitrogen, and aromatic ring structures, which is why Group I oils typically have an amber to golden-brown color and contain significant levels of aromatics (10-30%).

In contrast, Group II base oil production via hydroprocessing virtually eliminates aromatic molecules (typically less than 0.1% or even <0.01%), resulting in a clear, colorless base oil with very low sulfur and nitrogen content. This higher purity directly translates to superior performance characteristics. The shift from solvent refining (Group I) to hydroprocessing (Group II) represents a paradigm change in base oil production, moving beyond mere separation towards chemical conversion. While solvent refining was effective for its time, its reliance on solubility differences was limiting, leaving significant amounts of less stable aromatic and sulfur-containing compounds. Hydroprocessing, on the other hand, actively breaks down these undesirable molecules using hydrogen under high pressure and temperature, converting them into stable saturated hydrocarbons. The near-complete removal of aromatic molecules is a profound achievement, as aromatics are highly susceptible to oxidation and contribute to sludge and varnish formation in lubricants. This fundamental change in chemical composition signifies a deliberate and technologically intensive pursuit of a “purer base oil” that is less reactive and inherently more stable. This technological leap has not only enabled the creation of lubricants with significantly improved performance but has also been instrumental in meeting increasingly stringent environmental regulations by reducing harmful by-products and extending lubricant life.

Group 3 Base Oils: More Severe Refining, Higher Performance

Group 3 base oils are also produced from crude oil products and through hydrogen-based processes, similar to Group II. However, the hydrocracking process for Group 3 is “more severe,” operating at even higher temperatures and pressures. This “longer and more complex process” is designed to achieve an even purer base oil with a Viscosity Index (VI) consistently above 120. Due to their highly severe refining, Group III base oils are sometimes described as “synthesized hydrocarbons.”

3. Key Characteristics and Performance Properties of Group 2 Base Oils

The meticulous hydroprocessing in Group 2 base oil production imbues them with a superior set of physical and chemical properties that significantly enhance lubricant performance:

- Clarity and Color: A hallmark of Group II base oils is their clear, colorless appearance, often described as “water-white.” This results from extensive hydrotreating, which effectively removes impurities that impart color to less refined base oils.

- Oxidation Stability: Group 2 base oils exhibit significantly better antioxidant properties and oxidation stability compared to Group I. This is mainly due to their high content of saturated compounds and the near-complete removal of reactive aromatic molecules, leading to longer lubricant life and stable performance.

- Thermal Stability: These base oils demonstrate excellent resistance to thermal degradation. Their stable molecular structure allows them to maintain critical lubricating properties even at high operating temperatures, reducing the formation of deposits and sludge.

- Viscosity Index (VI): While the API definition for Group II specifies a VI between 80 and 120, these oils typically achieve a VI well over 100, often in the 100 to 120 range. A higher VI indicates less change in viscosity with temperature fluctuations, ensuring consistent lubrication across a broad operating range.

- Pour Point: Thanks to catalytic dewaxing, Group 2 base oils have excellent low-temperature properties and significantly lower pour points. This ensures fluidity and pumpability even in cold environments, critical for cold starts.

- Flash Point: Group 2 base oils typically have a high flash point, a crucial safety feature indicating resistance to ignition even under high-temperature operating conditions.

- Low Volatility (NOACK Stability): Group II oils exhibit low volatility for a given viscosity grade, which is crucial for reduced oil consumption, minimized emissions, and maintaining optimal viscosity throughout the lubricant’s lifespan.

- High Saturated Content: With over 90% saturates, Group 2 base oils possess a highly stable molecular structure, directly responsible for their excellent oxidation stability and resistance to chemical breakdown under stress.

- Low Sulfur Content: Sulfur content is consistently less than 0.03%, minimizing the potential for corrosive by-products and contributing to enhanced oil stability and reduced environmental impact.

- Low Aromatics: A key distinguishing feature is their very low aromatic content, typically less than 1% and often below 0.1%. This significantly contributes to their improved stability and purity, contrasting sharply with Group I oils (10-30% aromatics).

Unparalleled Advantages of Group II Base Oils

Group II base oils offer superior performance compared to Group I due to their higher purity, enhanced oxidation and thermal stability, lower sulfur and aromatic content, and improved viscosity index. These characteristics lead to extended lubricant life, reduced deposits, and better environmental compatibility.

The Challenge of Solvency and Its Solutions

Despite their numerous advantages, Group II base oils present a significant challenge in lubricant formulation: their lower solvency compared to Group I oils. This is because Group II oils are highly saturated, non-polar hydrocarbons (isoparaffinic) and lack the natural polar species (like hetero-cycles and alkylated aromatics) abundant in Group I oils, which help dissolve lubricant additives. This reduced solvency can make it difficult to effectively dissolve essential lubricant additives, potentially compromising critical performance parameters such as dispersancy (the ability to keep contaminants suspended) and seal compatibility. This issue is particularly pronounced in demanding applications like marine and gas engine oils, where heavy fuel contamination can introduce large polyaromatic species (asphaltenes). If the lubricant cannot adequately manage these asphaltenes, they can agglomerate and form “black sludge” and deposits, leading to piston deposits, clogged oilways, and oil starvation.

To overcome these solvency challenges, lubricant formulators must utilize novel additive systems or incorporate specific “solvency improvers” into their finished lubricant formulations. These improvers are typically polar compounds such as esters or alkylated aromatics that enhance the base oil’s ability to dissolve and disperse additives. For example, companies like Infineum have developed specialized additive booster packages, such as those used with salicylate-based TPEO (Trunk Piston Engine Oil) additive technology, specifically to address asphaltene management deficiencies in Group II marine engine oils.

The increased purity of Group II base oils, achieved through extensive hydroprocessing, leads to superior inherent properties like oxidation stability and high VI. However, this same purity, characterized by the near-complete removal of polar and aromatic compounds, creates a paradoxical challenge: reduced solvency for the complex additive packages essential for modern lubricants. The “impurities” of Group I (aromatics, hetero-cycles) inadvertently provided a degree of solvency that Group II lacks. This means that simply replacing Group I with Group II in existing formulations is not a straightforward solution; rather, it necessitates a fundamental re-engineering of the entire additive system. This highlights a critical trade-off between the inherent performance benefits of a cleaner base oil and its compatibility with the complex chemical structures of modern lubricant additives. This inherent challenge drives continuous innovation in additive chemistry and necessitates closer collaboration between base oil manufacturers and additive suppliers. It also adds a layer of complexity and potentially cost to lubricant formulation, which can be a significant hurdle for smaller lubricant manufacturers who may lack the R&D resources to develop new additive systems. This dynamic emphasizes that the performance of a finished lubricant is a holistic outcome of both the inherent quality of the base oil and the sophisticated additive chemistry.

4. Grades and Applications of Group 2 Base Oils

Group 2 base oils span a wide range of viscosities, each optimized for specific applications. These grades are identified by the “N” series designation (for “Neutral”), where the number indicates approximate viscosity. Given the high purity of Group II, viscosity becomes the most critical differentiating factor in selecting the appropriate base oil.

Specific Group II Base Oil Grades and Their Applications:

-

N60 / N70 / N80 Base Oils:

- Description: These are the lightest Group II grades, known for their very low viscosity. They are produced through intense hydrocracking and hydroisomerization processes, resulting in exceptionally high purity.

- Applications: Primarily used in the formulation of high-performance engine oils, transformer oils, light hydraulic fluids, coolants, and as industrial solvents that require low volatility and high purity.

-

N100 Base Oil:

- Description: N100 is a light-to-medium viscosity base oil, offering high purity and stability. It’s produced via advanced hydroprocessing, providing excellent oxidation stability and a high Viscosity Index (VI).

- Applications: Widely used in the manufacturing of gasoline and diesel engine oils, industrial lubricants (such as light hydraulic and gear oils), metalworking fluids, and lubricant additives. It’s also suitable for compressor oils, textile oils, and automatic transmission fluids.

-

N150 Base Oil:

- Description: N150 is a medium viscosity grade that strikes a good balance between performance properties and accessibility. Also hydroprocessed, it boasts excellent thermal and oxidation stability along with a high Viscosity Index.

- Applications: As one of the most versatile Group II grades, N150 is used in formulating a broad range of automotive and industrial engine oils, hydraulic oils, gear oils, greases, and metalworking fluids. It’s also suitable for turbine oils and industrial compressors.

-

N220 Base Oil:

- Description: N220 is a higher viscosity base oil designed for heavier loads and elevated operating temperatures. Its inherent Group II purity and stability are maintained in this grade.

- Applications: Suitable for industrial gear oils, heavy-duty hydraulic fluids, high-performance diesel engine oils, turbine oils, and general industrial lubricants requiring a stronger film strength.

-

N300 Base Oil:

- Description: N300 offers even higher viscosity and is produced through intensive hydroprocessing. This grade is recognized for its excellent thermal and oxidation stability and ability to maintain viscosity at high temperatures.

- Applications: Ideal for high-performance industrial gear lubricants, heavy-duty hydraulic fluids, diesel engine lubricants, specialty greases, and process oils that demand high stability under severe conditions.

-

N400 / N500 / N600 Base Oils:

- Description: These are the heaviest Group II base oil grades, providing the highest viscosities within this group. They are products of highly severe hydroprocessing, delivering maximum oxidation stability, thermal stability, and Viscosity Index among mineral base oils.

- Applications: Primarily used in the formulation of heavy-duty industrial lubricants, ultra-high-performance engine oils, heavy gear oils, high-temperature/high-pressure greases, marine oils, and specialty lubricants requiring strong film retention and degradation resistance under the most extreme operating conditions.

“Group II Plus”: A Market-Driven Distinction

The informal term “Group II Plus” refers to Group II base oils exhibiting a slightly higher Viscosity Index, typically between 110 and 115. While not an official API-recognized category, it serves as a market-driven distinction to offer minor but valuable improvements in viscosity stability. This distinction acts as a bridge between Group II and Group III, providing near-Group III performance without the full cost or severity of its production.

5. Typical Technical Specifications for Select Group 2 Base Oil Grades

6. Applications of Group II Base Oils

Group II base oils have become the cornerstone of modern lubricant formulations due to their superior properties, coupled with an optimal balance of performance and cost-effectiveness. They find widespread application in both automotive and industrial sectors.

Automotive Lubricants:

The automotive sector is a primary consumer of Group II base oils, with demand increasing due to the continuous evolution of engine technologies and more stringent performance requirements:

- Engine Oils: Group II base oils are extensively used in formulating automotive engine oils, including those designed for modern passenger vehicles, high-performance racing engines, and heavy-duty commercial vehicles. Their improved oxidation stability and low volatility are crucial for meeting stringent emission standards and enabling extended drain intervals.

- Transmission Fluids: These oils are commonly found in formulations for modern industrial gear lubricants and automotive transmission fluids, where their thermal stability and purity contribute to enhanced protection and efficiency.

- Hydraulic Fluids: Group II base oils are widely employed in various hydraulic fluids, including high-performance formulations for heavy-duty applications and industrial equipment operating under harsh pressure and temperature conditions.

- Automatic Transmission Fluids (ATF): Their excellent thermal and oxidation stability also makes them suitable for use in advanced ATFs in vehicles.

Industrial Applications:

Beyond the automotive sector, Group II base oils meet a diverse range of industrial needs:

- Metalworking Fluids: They are key components in advanced metalworking fluids and specialized coolants used in machining and manufacturing processes, where their purity and stability are beneficial.

- Compressor Oils: Used in compressor oil formulations, leveraging their low volatility and oxidation resistance to extend equipment life.

- Heat Transfer Fluids: Their thermal stability makes them suitable for various heat transfer fluid applications.

- Process Oils: Employed as process oils in diverse manufacturing operations, where their consistent quality and low impurity levels are advantageous.

- Plastics and Polymers: Group II base oils find application as additives in the plastics and polymer industries, acting as rubber/TPE extenders and components in adhesives and sealants due to their non-staining properties and stability.

- Coatings and Spray Oils: Also used in various coating formulations and as spray oils, benefiting from their clear color and low odor.

- Transformer Oils: Specific light viscosity grades, such as 2.5 cSt, are used as base stocks for transformer oils, valued for their good detergency properties, adequate viscosity index, and low pour point.

Agricultural Applications:

Their purity and stability also extend their utility to some agricultural applications.

7. Conclusion

Group II base oils have definitively established themselves as the cornerstone of modern lubricant formulations, owing to their advanced production via meticulous hydroprocessing and favorable economics. These base oils deliver an unparalleled balance of purity, performance, and cost-effectiveness. Their distinguishing characteristics include exceptional oxidation stability, high viscosity index, minimal sulfur and aromatics, and impeccable clarity. These attributes make them indispensable for meeting the increasingly stringent demands of contemporary automotive and industrial applications, representing a significant leap in base oil technology that offers superior longevity, efficiency, and environmental compatibility compared to their Group I predecessors.

The trajectory for Group II base oils points towards continued growth and market dominance. This sustained prominence will be driven by several factors:

- Evolving Global Regulatory Landscape: Demanding higher performance and reduced environmental impact.

- Relentless Pursuit of Extended Lubricant Drain Intervals: A key goal for end-users.

- Ongoing Industrial Modernization: Requiring more advanced lubricants across sectors worldwide.

- Increasing Cost Competitiveness: Group II’s price advantage over Group I.

- Continuous Innovation in Additive Technology: Addressing their unique solvency characteristics.

- Growing Emphasis on Sustainability: Evident through the increasing adoption of recycling processes for Group II oils, further solidifying their pivotal role in shaping the future of the global lubricants industry.

Their versatility, coupled with their increasingly robust environmental credentials, ensures their long-term significance as a fundamental component in high-performance lubrication.

I’m looking to switch from Group I to Group II base oil for my heavy-duty engine oil formulation. The article mentions a solubility challenge with Group II. What’s the biggest issue, and can I solve it just by increasing the amount of dispersant additives?

The core issue is the very low aromatic content of Group II (which is why they’re so stable). You can’t solve it just by bumping up dispersants. You often need entirely new additive chemistries or specific solubility enhancers to keep polar additives and sludge precursors dissolved, especially under conditions of heavy soot or fuel contamination.