Base Oil Production Process: Everything You Need to Know

Base oil is the very heart of any industrial or automotive lubricant. This vital component makes up over 70% to 95% of the final volume of engine oils, gear oils, hydraulic fluids, and other lubricants. The quality and type of base oil significantly determine the performance, stability, and lifespan of the finished lubricant. But how exactly is base oil produced? What are the differences between its various types, and why do they have different viscosities? In this comprehensive article, we’ll delve into the base oil manufacturing process, its various classifications, and the factors influencing viscosity.

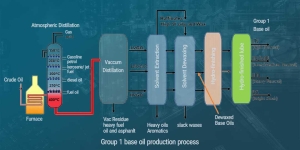

Overview of Base Oil Production

Base oil production is a complex, multi-stage process that primarily begins with crude oil. The main steps involved are as follows:

- Atmospheric Distillation: In this initial stage, crude oil is heated to high temperatures in atmospheric distillation towers. Lighter crude oil components, such as gasoline, kerosene, and diesel, vaporize at lower temperatures and exit from the top of the tower. The heavier residue, known as “fuel oil” or “bottoms cut,” is then used for subsequent base oil separation stages.

- Vacuum Distillation: The materials obtained from atmospheric distillation are transferred to vacuum distillation towers. In this stage, a reduced pressure lowers the boiling points of the compounds, allowing for the separation of heavier components, including various oil cuts (which will later become base oils) and asphalt, without the need for extremely high temperatures that could lead to thermal decomposition. These oil cuts typically include spindle oils, lubricating oils, and encapsulation oils.

- Solvent Extraction/Deasphalting: The oil cuts from vacuum distillation contain undesirable compounds such as asphaltenes, resins, and polycyclic aromatic compounds. These can reduce stability and increase sludge formation in the final oil. In this step, harmful compounds are removed from the oil cuts using solvents like furfural or NMP.

- Solvent Dewaxing: Even after solvent extraction, the refined oil cuts still contain waxy paraffins. At low temperatures, these waxes can crystallize, increasing the pour point and causing the oil to gel. In the solvent dewaxing stage (typically using methyl ethyl ketone or toluene/MEK), the oil is chilled, and the waxes precipitate. The solid waxes are then separated from the oil.

- Hydrotreating/Finishing: In this final stage, the base oil undergoes hydrotreating to remove remaining impurities, improve color and stability, and reduce sulfur content. This process involves exposing the oil to hydrogen and a catalyst at high temperatures and pressures. This step significantly enhances the final quality of the base oil.

Understanding Viscosity Differences in Base Oils

Viscosity is the most crucial physical property of base oil, indicating its resistance to flow. The viscosity of different base oil types depends on the following factors:

- Molecular Size and Structure: Base oils with larger molecules and longer carbon chains exhibit higher viscosity. These larger molecules offer greater resistance to relative movement.

- Molecular Weight: Directly related to molecular size, a higher average molecular weight generally means higher viscosity.

- Type of Crude Cut: Heavier crude oil cuts (which are distilled at higher temperatures) contain larger molecules and consequently have higher viscosity.

- Refining Process: Refining processes can influence the molecular size distribution and the removal of impurities that affect viscosity. For example, more complete wax removal can improve the Viscosity Index (VI) but doesn’t necessarily alter the base viscosity.

Simply put, base oils with different viscosities are obtained either from different (heavier) crude oil cuts or by adjusting production process parameters (such as the intensity of molecular cracking in more advanced processes).

Differences in Production Processes for Base Oil Groups I, II, III, IV, and V

The Society of Automotive Engineers (SAE) and the American Petroleum Institute (API) categorize base oils into five main groups based on their chemical composition and production process. The key differences in production and final product specifications are as follows:

Group I Base Oil Production Process:

- Production Process: This is the oldest and most traditional type of base oil. Its production primarily involves solvent extraction, solvent dewaxing, and final finishing with clay treatment or mild hydrotreating.

- Characteristics: Contains less than 90% saturated compounds and/or more than 0.03% sulfur. Viscosity Index (VI) ranges from 80 to 120. Due to higher aromatic and sulfur content, these oils have lower thermal and oxidation stability.

Group II Base Oil Production Process:

- Production Process: The production of this group involves more severe hydrocracking and hydroisomerization processes. These processes break down long, complex molecules and modify their structure to produce more saturated compounds and remove undesirable elements.

- Characteristics: Contains over 90% saturated compounds and less than 0.03% sulfur. Viscosity Index (VI) ranges from 80 to 120. They offer significantly better thermal and oxidation stability than Group I oils and also have a lighter color.

Group III Base Oil Production Process:

- Production Process: Also known as “Very High Viscosity Index (VHVI)” base oils, these are produced using highly advanced and more severe hydrocracking and hydroisomerization processes than Group II. The main goal is to maximize the conversion of undesirable compounds into saturated compounds and iso-paraffinic structures.

- Characteristics: Contains over 90% saturated compounds and less than 0.03% sulfur. Viscosity Index (VI) is above 120. These oils boast excellent thermal and oxidation stability, low volatility, and very good low-temperature performance. Many synthetic or semi-synthetic engine oils utilize Group III base oils.

Group IV (PAO) Base Oil Production Process:

- Production Process: These are true synthetic base oils, produced through the polymerization of alpha-olefins (PAO – Polyalphaolefins). This process involves chemical synthesis from ethylene or butene as raw materials.

- Characteristics: Uniform and highly stable molecular structure. Very high Viscosity Index (typically above 130). Exceptional thermal and oxidation stability, excellent performance at very low and high temperatures, very low volatility, and a very low pour point. PAOs are generally more expensive than petroleum-derived base oils.

Group V Base Oil Production Process:

- Production Process: This group encompasses all other base oils not classified in the previous four groups. It is a highly diverse group, including synthetic base oils such as esters, polyglycols (PAG), phosphate esters, silicones, and more. Each has its own specific production process, starting with chemical synthesis.

- Characteristics: Possess highly varied physical and chemical properties, offering unique characteristics based on their specific application, including resistance to very high temperatures, high solubility for additives, inherent lubricating properties, and more. For example, esters are often used in combination with PAOs in finished synthetic oils due to their high solubility and polar properties.

Conclusion

The base oil manufacturing process is the fundamental first step in producing a wide range of essential lubricants. Understanding the differences between various base oil groups and how production processes influence their final properties is crucial for the correct selection and application of lubricants. As technology advances, the production of higher-quality and improved-performance base oils will continue to meet the evolving needs of various industries and new-generation vehicles.

Frequently Asked Questions (FAQ)

- What is the main difference between mineral and synthetic base oils? Mineral base oils (like Group I, II, III) are derived from crude oil, while synthetic base oils (like Group IV and V) are manufactured through complex, controlled chemical processes from simpler molecules. Synthetic oils generally offer superior performance characteristics at high and low temperatures, greater stability, and longer lifespan.

- Why does base oil need to be refined? Crude oil contains numerous impurities such as asphaltenes, sulfur, nitrogen, aromatic compounds, and waxes. These impurities can reduce oxidation stability, lead to sludge formation, increase deposits, and cause the oil to gel at low temperatures. Refining base oil removes these harmful compounds, improving the quality and performance of the final oil.

- Are all base oils “colorless”? No. Group I base oils typically have an amber-yellow color, while Group II and III base oils are lighter and nearly colorless due to more advanced refining processes. Synthetic base oils (Group IV and V) are also generally colorless.

- What is the Viscosity Index (VI), and why is it important? The Viscosity Index (VI) is a measure of how much an oil’s viscosity changes with temperature variations. An oil with a high VI exhibits less viscosity change with temperature fluctuations, meaning it won’t thin out excessively at high temperatures or become too thick at low temperatures. This characteristic is crucial for consistent lubricant performance across various temperature conditions.

- Can different base oil groups be mixed? Yes, in many cases, different base oil groups can be mixed, especially in the production of finished lubricants. However, it’s always recommended that this be done by specialists and with consideration for chemical compatibility and the final product’s properties to prevent performance issues. For example, many semi-synthetic engine oils are a blend of Group II and Group III base oils.

What does the Viscosity Index (VI) mean, and why is it important for a lubricating oil?

The Viscosity Index (VI) is a measure of how much an oil’s viscosity changes with temperature. A higher VI means less viscosity change with temperature fluctuations, indicating the oil won’t thin out too much at high temperatures or thicken too much at low temperatures. This property is crucial for the stable and optimal performance of a lubricant across a wide range of temperature conditions.

Hello! Someone in my Facebook group shared this website with us so I came to give it a look. I’m definitely loving the information. I’m book-marking and will be tweeting this to my followers! Superb blog and outstanding design.

What is the key process difference that separates the quality of Group I, Group II, and Group III base oils?

The primary difference lies in the severity of the hydroprocessing. Group I oils are made using traditional solvent refining methods. Group II oils are produced through more severe hydrocracking and hydrotreating, providing higher purity and saturation than Group I. Group III oils are produced using highly advanced hydroisomerization processes resulting in exceptional purity, a Viscosity Index (VI) above 120, and near-synthetic quality.

Does a high viscosity in a base oil necessarily mean it has better quality compared to thinner oils?

No, viscosity only indicates flow resistance. The quality of the oil depends on parameters like the viscosity index and the level of impurities. Each grade (thick or thin) is designed for a specific application in engines or industry.