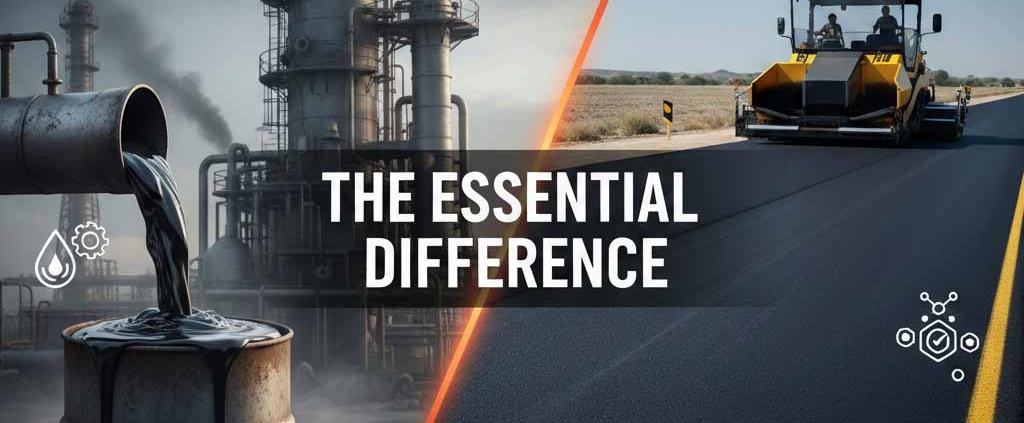

Vacuum Bottom vs. Bitumen: A Technical and Commercial Comparison

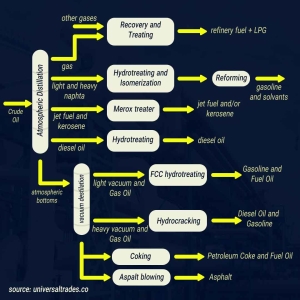

Understanding the relationship between Vacuum Bottom (VB) and Bitumen is crucial for anyone involved in the oil, gas, and construction industries. While these terms are often used interchangeably by mistake, they represent different stages of the refining process.

What is Vacuum Bottom (VB)?

Vacuum Bottom is the heaviest, thickest residue that remains at the bottom of the vacuum distillation tower after lighter fractions like gas oil and lubricants are extracted. It is a complex mixture of heavy hydrocarbons with high molecular weight.

-

Primary State: Extremely viscous, dark, and semi-solid at room temperature.

-

Role in Industry: It serves primarily as the feedstock (raw material) for the production of various bitumen grades.

What is Bitumen?

Bitumen is an engineered hydrocarbon product derived from Vacuum Bottom. It is specifically processed to meet international standards (such as ASTM or EN) for infrastructure projects.

-

Primary State: Viscous and waterproof with high adhesion properties.

-

Role in Industry: The final product used in asphalt for road paving, roofing membranes, and industrial sealants.

Key Differences: Vacuum Bottom vs. Bitumen

To better understand their distinctions, let’s compare them across four critical dimensions:

1. Production & Refining Process

-

Vacuum Bottom: Obtained directly from the vacuum distillation of crude oil. It is a “straight-run” residue.

-

Bitumen: Produced by further refining VB. The most common method is air blowing (oxidation) in a Bitumen Refinery, which alters the molecular structure to achieve desired hardness and penetration.

2. Physical & Chemical Properties

While both are dark and viscous, Bitumen has standardized specifications.

-

VB Properties: Inconsistent and dependent on the type of crude oil source.

-

Bitumen Properties: Features specific Penetration Grades (e.g., 60/70, 80/100) and Viscosity Grades (e.g., VG-30) tailored for different climates.

3. Industrial Applications

-

VB: Limited direct use; mainly used as fuel oil in power plants or as a base for Natural Bitumen alternatives.

-

Bitumen: Diverse applications including road surfacing, waterproofing, and pipe coating.

| Feature | Vacuum Bottom (VB) | Bitumen |

| Nature | Raw Material / Feedstock | Finished Product |

| Processing | Distillation Residue | Oxidized / Blended |

| Consistency | Variable | Highly Standardized |

| Marketability | High (as Feedstock) | High (as End Product) |

Can Vacuum Bottom be used directly as Bitumen?

In some rare cases, if the crude oil source is of exceptional quality, the “straight-run” Vacuum Bottom may meet the requirements for a paving binder. However, in 90% of industrial cases, VB must undergo oxidation to improve its Softening Point and Durability before it can be sold as marketable bitumen.

Technical Resources & Deep Dives

To gain a deeper understanding of the bitumen supply chain and technical specifications, explore our comprehensive guides:

Product Selection

-

Introduction to Bitumen Types: A complete breakdown of Emulsions, Cutbacks, and Penetration grades.

-

Introduction to Vacuum Bitumen: Specifics on the first stage of refined bitumen.

-

Hot and Cold Bitumen: Which application is right for your climate?

Global Market Insights

-

Top Bitumen Producing Countries: An analysis of the global leaders in VB and Bitumen exports.

-

Bitumen Articles & Vacuum Bitumen Articles: Access our full library of technical whitepapers.

Leave a Reply

Want to join the discussion?Feel free to contribute!