Granular Sulfur: Key Applications and Properties

Sulfur, a chemical element with the symbol S and atomic number 16, has long played a significant role in various industries. This yellow substance, found in nature and also obtained as a byproduct of refining petroleum products and natural gas, is now offered in various forms. Among these forms, granular sulfur has gained a special place due to its unique properties and ease of use. In this article, we will comprehensively examine granular sulfur, its advantages compared to other types of sulfur, and its important applications in various industries.

Sulfur and How It Is Produced:

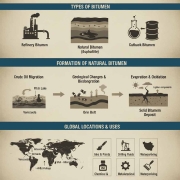

Sulfur exists in volcanic regions and mines, but today it is mainly extracted from the processing of crude oil and natural gas. In refineries and gas processing units, during the process of removing sulfur compounds to improve fuel quality and reduce pollution, elemental sulfur is produced. This recovered sulfur, with its high purity and relative availability, is the primary source for meeting the needs of industries for this material.

What is Granular Sulfur and What is the Difference?

Granular sulfur is a type of pure sulfur that is produced in the form of small, spherical or semi-spherical particles of a specific size. This granulation process, which usually involves spraying molten sulfur and cooling it, creates a product with improved physical properties. Compared to powdered sulfur or lump sulfur, granular sulfur offers several advantages that make it preferred in many applications.

Key Properties of Granular Sulfur:

Granular sulfur is suitable for a variety of industrial applications due to its unique physical and chemical properties. Some of the most important of these properties include:

- Easier Handling and Transportation: Its granular form makes it easy to transport and reduces the risk of sticking and clogging in transportation and storage equipment. This lowers logistics costs and increases safety.

- Dust Reduction: It produces significantly less dust compared to powdered sulfur. This keeps the work environment healthier and prevents material waste. It also significantly reduces the risk of explosion caused by suspended sulfur particles in the air.

- Better Mixing and Reaction: The suitable contact surface of granular sulfur particles facilitates uniform mixing with other materials in production processes. In some chemical reactions, this form can also improve speed and efficiency.

- Resistance to Caking: Powdered sulfur tends to cake over time and under certain conditions, making it difficult to use. Granular sulfur is more resistant to caking due to its regular shape and reduced contact surface between particles, making it more suitable for long-term storage.

- Direct Usability: In many cases, granular sulfur can be used directly without the need for additional processing such as grinding, which saves time and cost.

- High Purity: Granular sulfur produced from refinery sources typically has high purity, which is important for many sensitive industrial applications.

The Difference Between Granular Sulfur and Other Types of Sulfur:

Sulfur is produced in various forms such as powder, lumps, and flakes, each with its own specific properties and applications. The main differences between granular sulfur and these forms are:

- Powdered Sulfur: Has very fine particles and a high contact surface, making it suitable for some reactions, but it is difficult and dangerous to handle and produces a lot of dust. It also cakes easily.

- Lump Sulfur: Comes in large and irregular pieces and must be crushed before use, which is time-consuming and costly. Its transportation and storage are also difficult.

- Flake Sulfur: Comes in thin layers and is used in some specific industries, but it is harder to handle than granular sulfur and there is a risk of breakage and dust production.

In contrast, granular sulfur offers an ideal combination of ease of use, safety, and efficiency. Its regular shape and uniform particle size make handling easier, reduce dust, and increase resistance to caking.

Diverse Applications of Granular Sulfur in Industries:

Granular sulfur has a wide range of applications in various industries due to its desirable properties:

- Agriculture: As a fertilizer, it improves soil quality, increases nutrient absorption, and helps control diseases and pests. It significantly increases crop yields, especially in alkaline soils.

- Sulfuric Acid Production: The main raw material in the production of this vital chemical used in making fertilizers, synthetic fibers, detergents, and dyes.

- Rubber and Plastics Industries: Used in the vulcanization process to increase the strength and durability of rubber. It is also used as an additive in the production of some plastics.

- Mining Industries: Used as a reactant in the extraction and processing of some metals such as copper and uranium.

- Paper Production: Used in the sulfite pulping process to separate cellulose fibers from wood.

- Water and Wastewater Treatment: Used as an energy source for denitrifying bacteria in some biological treatment methods.

- Construction Industries: Used as an additive in the production of some cements and concretes to improve mechanical properties and durability.

- Explosives Production: One of the main components in the production of some explosives and fireworks.

Conclusion:

Granular sulfur, with its advantages such as ease of handling, dust reduction, better mixing, and resistance to caking, has become an important raw material in various industries. Its production from petroleum products and natural gas, in addition to reducing pollution, meets the growing needs of the market. Its wide applications in agriculture, sulfuric acid production, rubber and plastics, mining, and many others, demonstrate its key role in the economy and sustainable industrial development. Considering these properties, the use of granular sulfur is expected to continue to grow.

Frequently Asked Questions (FAQ)

1. How is Granulated Sulfur produced?

Granulated sulfur is typically produced by spraying molten sulfur and then rapidly cooling it down (often using water or air) in specialized towers (like the prilling or granulation process). This process forms the sulfur into small, spherical or semi-spherical, uniform particles.

2. When is it best to use Granulated Sulfur?

Granulated sulfur is the best choice when easy handling, reduced dust, long-term storage (clump resistance), and uniform mixing with other materials are important. This form is highly common in agricultural applications (as fertilizer) and sulfuric acid production.

3. Is Sulfur toxic to humans?

Elemental Sulfur (the form produced as granulated sulfur) is low in toxicity to humans on its own. However, sulfur compounds like Sulfur Dioxide () or Hydrogen Sulfide () are highly toxic and dangerous. Powdered sulfur also poses inhalation and explosion risks due to dust, which granulated sulfur significantly reduces.

4. What is the typical purity of granulated sulfur?

Granulated sulfur produced as a byproduct of oil and gas processing (recovered sulfur) usually has a very high purity (often above 99.5%), making it suitable for sensitive industrial applications.

5. What is the main advantage of granulated sulfur over lump sulfur?

The main advantage is direct usability and ease of handling and storage. Lump sulfur must be crushed before use, which is costly and time-consuming, whereas granulated sulfur requires no additional processing.

Given the article’s explanation of the advantages of granular sulfur over powdered sulfur (such as reduced dust and explosion hazards), if I own a chemical fertilizer or rubber manufacturing plant that consumes large quantities of sulfur annually, what practical and direct impacts would choosing granular sulfur have on my work environment, worker health, and operational costs? Is this difference significant enough to justify the economic shift from powdered to granular?

Your question addresses one of the primary concerns for large industrial units: safety, workplace health, and cost optimization. Yes, choosing granular sulfur over powdered sulfur in a chemical fertilizer or rubber manufacturing plant that consumes large quantities of sulfur annually will have significant practical and direct impacts, providing a very strong economic and safety justification for this change.

Practical and Direct Impacts of Choosing Granular Sulfur:

Significant Improvement in Worker Health and Safety:

Dust Reduction: This is the most crucial advantage. Powdered sulfur dust easily becomes airborne and is inhaled by workers. Long-term inhalation can lead to respiratory problems, eye, and skin irritation. Granular sulfur, due to its larger particle size and shape, drastically reduces the amount of airborne dust, leading to improved air quality in the workplace and a reduction in related occupational diseases.

Reduced Explosion Risk: Powdered sulfur dust, at certain concentrations in the air, is highly flammable and explosive. This risk is a serious threat in plants handling large volumes of sulfur. Granular sulfur, by producing significantly less dust, dramatically lowers this explosion risk, making the work environment much safer.

Easier Cleanup: The workplace becomes less contaminated with sulfur dust, which makes cleaning and maintenance processes simpler and faster.

Reduced Operational Costs and Increased Efficiency:

Savings in Handling and Transportation: The article mentions that granular sulfur is easier to handle and transport, reducing the risk of sticking and clogging in equipment. This translates to lower logistics costs and less wear and tear on equipment.

Reduced Material Waste: With less dust, the amount of sulfur lost during transfer or storage is noticeably reduced, which is an economic saving in itself.

Resistance to Caking: Powdered sulfur tends to cake over time and under certain conditions, making its unloading, transfer, and use problematic and often requiring additional labor or equipment to break up clumps. Granular sulfur, due to its uniform shape, is more resistant to caking, which speeds up processes and reduces the need for manual intervention.

Direct Usability: In many processes, granular sulfur can be used directly without the need for additional, costly, and time-consuming grinding, saving both energy consumption and equipment costs.

Economic Justification for the Shift:

Based on the above points, yes, there is a strong and logical economic justification for shifting from powdered to granular sulfur. Although the initial purchase price of granular sulfur might be slightly higher than powdered sulfur, its long-term benefits, including:

Reduced health and safety-related costs (occupational illnesses, accidents).

Decreased need for complex ventilation and filtration systems.

Reduced material waste.

Lower maintenance and equipment depreciation costs.

Increased speed and efficiency in production processes.

Reduced labor costs for addressing caking issues or cleaning. All these factors lead to a significant return on investment in the long run, and additionally, they address a company’s social and environmental responsibilities. Ultimately, choosing granular sulfur is an investment in productivity, safety, and operational sustainability.

What is granular sulfur, and why does it have advantages over other forms of sulfur (such as powdered or lump) in various industries?

Thank you for your careful reading of the article. Here is the answer to your question:

Granular sulfur is a type of pure sulfur produced in the form of small, spherical or semi-spherical particles of a specific size. This granulation process is typically achieved by spraying molten sulfur and then cooling it.

Advantages of Granular Sulfur over Other Forms of Sulfur:

Due to its improved physical properties, granular sulfur offers several advantages over powdered or lump sulfur, making it preferred in many industrial applications:

Easier Transportation: Its granular form allows for easy handling and reduces the risk of sticking and clogging in transportation and storage equipment, which in turn lowers logistics costs and enhances safety.

Reduced Dust: It produces significantly less dust compared to powdered sulfur. This contributes to a healthier work environment and prevents material loss. It also substantially reduces the risk of explosions caused by airborne sulfur particles.

Resistance to Caking: Powdered and even flaked sulfur tend to cake over time, but granular sulfur, due to its regular shape and reduced contact surface area between particles, is more resistant to caking and better suited for long-term storage.

Direct Usability: In many cases, granular sulfur can be used directly without the need for additional processing like grinding, which saves time and cost.

Better Mixing and Reaction: The appropriate surface area of granular particles facilitates uniform mixing with other materials in production processes.

Overall, granular sulfur provides an ideal combination of ease of use, safety, and efficiency, and these characteristics make it a desirable option in various industries.

The article mentions Granular Sulfur is derived from petroleum refining. Does the source (petroleum-derived vs. mined sulfur) affect the final purity of the granular product, and why is high purity so essential?

Yes, the source significantly impacts purity. Petroleum-derived sulfur (recovered sulfur) is typically produced through the Claus process, resulting in purity often exceeding $99.9\%$. This high purity is essential for critical chemical processes like Sulfuric Acid production, as impurities (like ash or hydrocarbons) can poison the catalysts and reduce the efficiency of the entire plant.

How does Granular Sulfur improve soil quality and nutrient uptake in agriculture?

Granular sulfur acts as a fertilizer, particularly in alkaline soils, by lowering the pH and creating a more acidic environment. This facilitates the dissolution and availability of essential nutrients like phosphorus and micronutrients, boosting crop yields.

Excellent article. For long-distance maritime shipping, the “Friability” of granular sulfur is a major concern. If the granules break easily during mechanical loading, they create the very dust you mentioned as a hazard. Does Universal Trades test for GPR (Granule Physical Resistance)? Handling safety at ports depends heavily on this.

Hello Mr. Chen! You’ve raised a professional point. Granule strength is as important as chemical purity. Our granular sulfur undergoes strict physical testing to ensure minimal breakdown during bulk loading and transit. By maintaining high physical resistance, we help our clients minimize the risk of sulfur dust fires and environmental contamination at discharge ports, making Universal Trades a reliable partner for global logistics.