Diesel Production Process: From Crude Oil to Heavy Vehicle Fuel

Diesel fuel is one of the most vital fossil fuels in the world today, playing a key role in transportation, industry, and energy generation. But have you ever wondered how this fuel is actually produced? This article comprehensively examines the process of producing diesel from crude oil, highlights the key differences in the production of various types of diesel, and discusses the importance of this process in meeting global demand.

Crude Oil: The Starting Point for Diesel Production

It all begins with crude oil. Crude oil is a complex substance, a mixture of various hydrocarbons extracted from deep within the earth. To transform this dark, viscous liquid into usable diesel fuel, it must undergo intricate refining processes.

Key Stages of Diesel Production

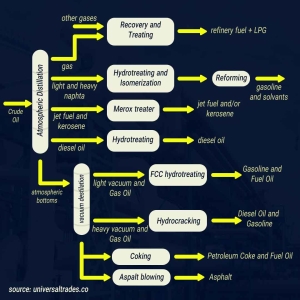

The production of diesel primarily occurs in oil refineries and involves several fundamental stages:

- Atmospheric Distillation: This is the first and most crucial stage. In this process, crude oil is heated to approximately 350-400 degrees Celsius and then fed into a distillation tower. Inside this tower, the different components of crude oil separate based on their varying boiling points. Lighter hydrocarbons (like gasoline and liquefied petroleum gas) condense and are collected at the top of the tower, while heavier hydrocarbons (such as diesel, kerosene, and fuel oil) gather at the bottom. The diesel cut is typically extracted from the distillation tower within a temperature range of 250-350 degrees Celsius.

- Hydrotreating: The diesel cut obtained from atmospheric distillation still contains impurities such as sulfur, nitrogen, and heavy metals. The presence of these impurities can damage vehicle engines, contribute to environmental pollution, and reduce fuel performance. Therefore, the diesel cut is then directed to a hydrotreating unit. In this unit, the diesel cut is subjected to high pressure and temperature in the presence of a catalyst and hydrogen. Hydrogen reacts with sulfur and nitrogen to form hydrogen sulfide (H2S) and ammonia (NH3) respectively, which are then removed from the fuel. This process significantly reduces the sulfur content in the diesel.

- Secondary Processes (If Required): In some cases, depending on the specific type of diesel needed, additional secondary processes may be applied:

- Pour Point Reduction: For diesel fuels used in cold climates, it’s essential to lower the pour point (the temperature at which the fuel begins to solidify). This is typically achieved through the addition of additives or specific processes like catalytic isomerization.

- Cetane Number Improvement: The cetane number is a measure of diesel fuel’s combustion quality. A higher cetane number indicates smoother and more complete combustion. This improvement can be achieved through secondary processes or by adding specific additives.

- Additives: Finally, various additives are blended into the diesel to enhance its final properties and ensure it meets specific standards. These additives can include cetane improvers, antifoaming agents, corrosion inhibitors, detergents, and lubricity enhancers.

Differences in the Production Process of Various Diesel Types

Different types of diesel are primarily defined by their sulfur levels and ultimate applications. The variations in their production processes largely stem from the intensity and complexity of the hydrotreating stage and the presence of specific secondary processes:

- Conventional Diesel: This type of diesel, which was more common in the past, has a higher sulfur content compared to current standards. Its production process involves atmospheric distillation and basic hydrotreating, which reduces sulfur to some extent but doesn’t eliminate it completely.

- Ultra-Low Sulfur Diesel (ULSD): Today, ULSD is the global standard for most applications, particularly in transportation. Producing ULSD requires a much more advanced and efficient hydrotreating process. In this process, operating conditions (temperature, pressure, and catalyst type) are precisely controlled to reduce the sulfur content to less than 15 parts per million (ppm). This significant sulfur reduction is crucial due to strict environmental regulations aimed at minimizing sulfur dioxide (SO2) emissions from vehicle exhausts.

- Biodiesel: Biodiesel is produced from renewable sources such as vegetable oils (like soybean, rapeseed, or palm oil) or animal fats. Its production process is entirely different from petroleum-based diesel and involves a transesterification reaction. In this reaction, triglycerides (found in oils and fats) react with an alcohol (typically methanol) in the presence of a catalyst, forming mono-alkyl esters (biodiesel) and glycerol. Biodiesel can be used pure or blended with petroleum diesel (commonly B5, B20, etc.).

- Specialty Diesels: Some diesel fuels are produced for specific applications, such as:

- Winter Diesel: Characterized by a very low pour point to prevent gelling in extremely cold temperatures. The production of this type of diesel involves the addition of anti-gelling additives or specific pour point reduction processes.

- Jet Fuel (JP-8): While jet fuel shares similarities with diesel, it differs in specifications and production processes. For instance, jet fuel must have a higher flash point and be significantly purer in terms of impurities and water content.

The Environmental and Economic Importance of Diesel Production

The diesel production process, particularly the manufacturing of ULSD, plays a vital role in reducing air pollution and improving quality of life. The reduction of SO2 and particulate matter emissions enhances public health and contributes to the fight against climate change. Economically, efficient and sustainable diesel production is essential for meeting the global demands of transportation, industry, and agriculture.

Conclusion

Diesel production is a complex, multi-stage process that begins with crude oil and culminates in the final diesel product, ready for use in diesel engines. Advances in refining technology, especially in hydrotreating, have enabled the production of higher-quality and more environmentally friendly diesel. Given the world’s increasing reliance on diesel fuels, understanding this process and striving for its optimization is of paramount importance.

Frequently Asked Questions (FAQ)

- What is diesel and what are its uses? Diesel, also known as gas oil, is a liquid fuel primarily derived from the distillation of crude oil. Its main applications include fuel for diesel engines in heavy vehicles (trucks, buses), trains, ships, agricultural and construction machinery, as well as for electricity generation in diesel generators.

- Why is reducing sulfur in diesel important? Sulfur in diesel, when combusted, turns into sulfur dioxide (SO2), an air pollutant and a primary cause of acid rain. It can also damage vehicle exhaust systems and catalytic converters. Reducing sulfur helps decrease air pollution and extend engine life.

- What’s the main difference between conventional diesel and ULSD? The main difference lies in their sulfur content. Conventional diesel has a higher sulfur content, while ULSD (Ultra-Low Sulfur Diesel) has a sulfur content of less than 15 parts per million (ppm). This difference is due to the more advanced hydrotreating process used in ULSD production.

- How is biodiesel produced? Biodiesel is produced from renewable sources like vegetable oils (e.g., soybean or rapeseed oil) or animal fats through a chemical process called transesterification. In this process, triglycerides react with an alcohol (usually methanol).

- Are all types of diesel produced in refineries? Most types of diesel, especially petroleum-based diesel (conventional and ULSD), are produced from crude oil in oil refineries. However, biodiesel is produced in dedicated biodiesel production units from biological sources and can then be blended with petroleum diesel.

- What does the cetane number in diesel mean? The cetane number is a measure of diesel fuel’s ignition quality. A higher cetane number means the fuel ignites more smoothly, completely, and with a shorter ignition delay in a diesel engine. This translates to better engine performance and reduced combustion noise.

I’ve been browsing online greater than 3 hours nowadays, but I never discovered any fascinating article like yours. It?¦s pretty price sufficient for me. Personally, if all site owners and bloggers made just right content as you probably did, the web will be much more helpful than ever before.

How does the production process of Ultra-Low Sulfur Diesel (ULSD) differ from that of Biodiesel?

The production of ULSD is entirely petroleum-based, focusing on severe hydrotreating to reduce sulfur content to below $15 \text{ ppm}$. In contrast, Biodiesel is produced from renewable sources (like vegetable oils) using the key process of transesterification, which is a chemical reaction that converts triglycerides into mono-alkyl esters.

What is the real difference in diesel engine performance between a fuel with a low Cetane Number and one with a high Cetane Number? And regarding Winter Diesel, how is its Pour Point reduced to make it usable in severe cold?

A higher Cetane Number means a shorter ignition delay and a smoother, more complete combustion, which leads to reduced engine noise (knocking), easier cold starting, and lower emissions. To produce Winter Diesel, the Pour Point is lowered by adding Cold Flow Improvers (CFIs). These additives prevent the formation of large paraffin wax crystals that can cause the fuel to gel in very cold temperatures.