The World of Bitumen Refineries: Production, Types, and Applications

Bitumen, often synonymous with asphalt, is a crucial material in the world of construction and infrastructure. From the roads we drive on to the roofs over our heads, this versatile, black, viscous substance plays a fundamental role. Understanding the process and types of bitumen begins at the bitumen refinery.

What is a Bitumen Refinery?

A bitumen refinery is an industrial plant where crude oil is processed to separate its various hydrocarbon components. Bitumen is the heavy, non-volatile residue remaining after the lighter and middle fractions (like gasoline, diesel, and kerosene) have been removed. The refinery meticulously selects and processes specific crude oils rich in the heavy molecules needed for quality bitumen production. This process is essential for producing refined bitumen or natural bitumen alternatives that meet stringent engineering specifications.

The Bitumen Production Process

The bitumen production process primarily involves distillation, which can be further enhanced by other methods.

-

Atmospheric Distillation: Crude oil is heated to temperatures around to and then fed into a distillation column. Lighter components vaporize and are drawn off. The heavy, non-boiling residue remaining at the bottom is called atmospheric residue.

-

Vacuum Distillation: To remove the last traces of lighter fractions without causing thermal cracking of the molecules, the atmospheric residue is introduced into a vacuum distillation unit. The reduced pressure lowers the boiling temperatures, leaving behind the heavy vacuum bottom, which is the raw material for most commercial bitumen.

-

Further Processing (Optional):

-

Air Blowing/Oxidation: Hot air is blown through the vacuum bottom at elevated temperatures ( to ) to modify its properties, resulting in blown bitumen. This process increases the stiffness and softening point.

-

Solvent Deasphalting: Solvents like propane or butane can be used to separate bitumen components, especially for producing high-purity grades.

-

Blending: Different grades of bitumen or residues can be blended to achieve the exact technical specifications required for a final product.

-

Exploring the Types of Bitumen

Bitumen types are classified based on their physical properties and intended application, guiding the use of bitumen types across various industries.

-

Penetration Grade Bitumen (Paving Grade): This is the most common type for road construction. It is graded by a penetration test that measures the hardness (e.g., PEN 60/70, 80/100). The grade selection is crucial in determining the difference between quality and poor quality bitumen based on the local climate and traffic volume.

-

Oxidized Bitumen (Blown Bitumen): Produced by the air-blowing process, this bitumen has a higher softening point and lower temperature susceptibility, making it ideal for industrial applications like roofing felts, pipe coatings, and sound-dampening materials.

-

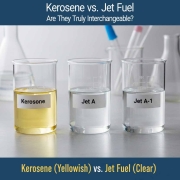

Cutback Bitumen: Created by blending penetration bitumen with a volatile solvent (e.g., kerosene, naphtha), this lowers the viscosity for easier application at lower temperatures. It is commonly used for priming road bases. The solvent evaporates after application, leaving the original bitumen binder behind.

-

Bitumen Emulsion: A stabilized suspension of tiny bitumen droplets in water, facilitated by an emulsifier. It’s a low-viscosity, cold-applied option used for cold-mix asphalt, tack coats, and slurry seals.

-

Polymer Modified Bitumen (PMB): Standard bitumen is enhanced with polymers (like SBS or EVA) to improve elasticity, durability, and resistance to temperature fluctuations and cracking. It’s often considered the best bitumen for high-stress pavements and demanding conditions.

Contact Us for Your Bitumen Needs

We understand that sourcing the right bitumen grade is critical to the success and longevity of your projects. Whether your needs demand standard paving grades, specialized blown bitumen, high-performance Polymer Modified Bitumen, or liquid cutback bitumen (solution), our team is equipped to provide high-quality products that adhere to international standards. Contact us today for consultation, competitive pricing, and reliable delivery to meet your exact specifications.

Conclusion

The world of bitumen refining is a complex and highly specialized sector, yielding an indispensable material for modern infrastructure. From the foundational step of crude oil distillation to the production of specialized grades like blown bitumen and cutback bitumen (solution), the refining process dictates the final properties and ultimate use of bitumen types. Making an informed choice between refined bitumen or natural bitumen and selecting the correct grade is key to ensuring a long and durable service life. When engineered correctly, bitumen provides a highly durable, cost-effective, and safe solution for paving and waterproofing needs globally.

Frequently Asked Questions (FAQ)

Is bitumen produced from coal or oil?

Bitumen is primarily a petroleum-based product, obtained as a residue during the refining of crude oil. It can also be found in natural deposits.

What is the raw material of bitumen?

The raw material for refined bitumen or natural bitumen is the heavy residue (vacuum bottom) remaining after the atmospheric and vacuum distillation of specific crude oils.

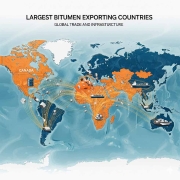

Which countries have the largest oil reserves in the world?

While reserves fluctuate, countries like Venezuela, Saudi Arabia, Iran, Canada (due to oil sands, which contain natural bitumen), and Iraq traditionally hold the largest proven reserves.

Dangers of using bitumen?

The main dangers relate to handling the hot material, which requires strict safety procedures to avoid burns. In its final application, minimal risk is present. Emissions during hot application must be managed.

Bitumen useful life?

When used in high-quality asphalt pavement, bitumen can provide a useful life of 15 to 20 years or more, depending on the quality of the bitumen, the asphalt mix design, traffic load, and maintenance.

What is a better alternative to bitumen?

For paving, alternatives include cement-based concrete pavement. For binders, there is research into bio-bitumen (plant-based) and other synthetic binders, but none have fully replaced bitumen yet due to cost and performance.

The best type of bitumen?

The best bitumen depends on the application. For high-traffic, temperature-variable roads, Polymer Modified Bitumen (PMB) is generally considered superior. For standard paving, a suitable Penetration or Viscosity Grade is best.

How does the viscosity grade system differ from the penetration grade system?

Penetration Grade measures the hardness at a single temperature (25), while Viscosity Grade (VG) classifies bitumen based on viscosity at a high service temperature (), offering a more performance-based grading, which helps in determining the difference between quality and poor quality bitumen for specific climatic conditions.

Can bitumen be recycled?

Yes, asphalt pavement, which is primarily bitumen and aggregate, is one of the most recycled materials in the world, often incorporated back into new road mixes as Reclaimed Asphalt Pavement (RAP).

What is the main difference between Oxidized Bitumen and Polymer Modified Bitumen (PMB)? Which one is better for waterproofing?

Oxidized bitumen is produced by air-blowing and has a high softening point, making it excellent for roofing and pipe coatings. PMB, however, contains polymer additives that enhance elasticity and tensile strength in roads against heavy traffic.

Great article on bitumen refining. I noticed you discussed both Penetration and Viscosity Grade (VG) systems. In many high-growth markets like India and Southeast Asia, there is a major shift from Pen 60/70 to VG-30. Could you clarify if the refining process for VG grades involves different distillation cuts, or is it purely a matter of more rigorous quality control during the blending stage?

Hello Dr. Rossi, thank you for your professional insight. While the fundamental distillation is similar, producing Viscosity Grade (VG) bitumen requires a much narrower “cutting” during the vacuum distillation process to ensure the viscosity at 60°C is strictly within the range. At Universal Trades, we ensure that our VG-30 and VG-40 products undergo high-precision blending and cooling processes, which provides much better resistance to rutting in tropical climates compared to traditional penetration-based grading.