Petroleum Coke (Petcoke) Grades & Uses: Needle, Sponge, Calcined – Full Guide

Petroleum coke, commonly abbreviated as Petcoke, is a solid, carbon-rich byproduct of the crude oil refining process, specifically derived from heavy hydrocarbon fractions like Fuel Oil and residual oil. It represents the final stage of the refinery process, transforming low-value residues into higher-value products. Its high carbon content makes it a crucial raw material and energy source across various industries.

What is Petcoke? Composition and Grade Differences

Petroleum coke is distinct from metallurgical coke, which is derived from coal. Petcoke is a carbonaceous solid derived exclusively from petroleum residues.

Key Components and Chemical Composition

The composition of petcoke is primarily fixed carbon, but its quality is defined by the levels of impurities:

| Component | Content Range | Significance |

| Fixed Carbon | 85% to 98.5% | Determines calorific value and material strength. |

| Sulfur | < 0.3% to > 6% | Critical pollutant; must be very low for Anode-Grade Coke. |

| Volatile Matter | High in Green Coke (up to 15%), Low in Calcined Coke ( <0.5\%). | Indicates the level of processing and stability. |

| Ash | Typically Low (0.01% to 1%) | Inorganic residue; must be ultra-low for high-purity applications. |

| Trace Metals | Vanadium (V), Nickel (Ni), Iron (Fe) | Impurities, especially critical in aluminum production. |

The Other Name for Petroleum Coke: Coke, Petcoke, or Coal?

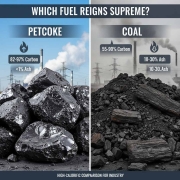

While often simply called “coke,” the proper names are Petroleum Coke or Petcoke. It is not the same as coal, though both are carbon-based fuels. Petcoke has a significantly higher calorific value (more energy per mass) and lower ash content than most coals but often a higher sulfur and heavy metal content, which impacts environmental regulations.

Types of Petcoke by Processing and Microstructure

Petroleum Coke is categorized primarily by its level of processing and its resulting microstructure (morphology). Understanding these types of Petcoke is essential for selecting the correct material.

1. Green Coke (Raw or Uncalcined Coke)

-

Description: The initial solid product obtained directly from the coking unit, containing residual hydrocarbons (volatile matter), moisture, and impurities like Sulfur.

-

Production: Produced in processes like the Delayed Coking Process.

-

Uses: Used directly as fuel (low-value Fuel Oil alternative) or, if high purity, as the raw material (Lub Cut) for producing Calcined Coke.

2. Calcined Petroleum Coke (CPC)

-

Description: A high-value, processed product resulting from heating Green Coke at extremely high temperatures (up to 1350°C) in rotary kilns. This process removes volatile matter and moisture, significantly increasing fixed carbon content and density.

-

Production: The Calcination Process (a key supplementary step).

-

Uses: The essential precursor for making high-quality carbon products, particularly pre-baked anodes for the aluminum industry (Anode-Grade Coke).

3. Sponge Coke

-

Description: Characterized by its highly porous, irregular, sponge-like structure. Produced from vacuum residues with medium levels of asphaltenes and impurities.

-

Production: Result of the Delayed Coking Process under certain operating conditions.

-

Uses: Primarily used for Anode-Grade Coke in the aluminum industry, provided its sulfur and metal content are low. Its porous structure also makes it suitable for gas and liquid absorption.

4. Needle Coke (Acicular Coke)

-

Description: A highly crystalline, premium Petcoke known for its long, fibrous, needle-like crystal structure, giving it low electrical resistance and low thermal expansion.

-

Production: Produced from highly aromatic feedstocks (e.g., decant oil) under specific high-pressure Delayed Coking Process conditions.

-

Uses: The preferred raw material for manufacturing high-power graphite electrodes used in electric arc furnaces for the steel industry, and increasingly for anodes in Lithium-Ion Batteries.

Other Types: Shot Coke and Fluid Coke

-

Shot Coke: Spherical, hard, and dense. Often associated with high asphaltene/sulfur feedstocks; typically Fuel-Grade with low market value.

-

Fluid Coke: Fine, powdery coke produced by the Fluid Bed Coking Process; used mainly for gasification and industrial boilers.

The Production Process of Petroleum Coke

Petcoke is produced through specialized refining processes designed to convert heavy oil fractions into lighter, more valuable distillates (like Diesel, Gasoline, and Kerosene) and solid carbon residue.

1. Delayed Coking Process

This is the most common method for producing Sponge Coke, Needle Coke, and Pellet Coke.

-

Heavy feedstock (e.g., vacuum residue) is rapidly heated and pumped into large coke drums under high pressure and temperature.

-

The heat cracks the large hydrocarbon molecules, and the residue solidifies into Green Coke inside the drums.

-

The difference between Needle Coke and Sponge Coke lies entirely in the quality of the feedstock (aromatic-rich for needle) and precise operating conditions (high pressure/recycle for needle).

2. Calcination Process

This secondary, post-production step is vital for making CPC.

-

Green Coke is slowly heated in rotary kilns to 980°C to 1350°C.

-

This heat eliminates nearly all volatile matter and moisture, resulting in highly pure Calcined Coke suitable for Anode-Grade applications.

Applications of Petroleum Coke (Petcoke Uses)

Petcoke is highly versatile, with its use determined by its purity (low Sulfur and metals).

1. Energy and Fuel (Fuel-Grade Coke)

-

Used as an economical and high-calorific-value fuel source in power plants, cement kilns, and industrial boilers, often as a substitute for coal.

2. Aluminum Production (Anode-Grade Coke)

-

Calcined Petroleum Coke (CPC), especially from low-sulfur Green Coke, is the key raw material for making pre-baked carbon anodes used in the Hall-Héroult aluminum smelting process.

-

How Petcoke is converted to Anode: CPC is crushed, mixed with coal tar Bitumen (binder), molded into green anodes, and then baked at high temperatures to form a durable, conductive carbon electrode. The high purity of the CPC is essential, as impurities contaminate the aluminum product.

-

3. Steel and Metal Production

-

Needle Coke is used to manufacture high-power graphite electrodes for electric arc furnaces (EAF) in the steel industry.

-

Metallurgical Coke (from coal) is the primary reducing agent in blast furnaces, but Petcoke derivatives can supplement various metallurgical processes.

4. Specialty Applications

-

Lithium-Ion Batteries: Specific grades of Needle Coke are processed for use as anode material in Li-ion batteries.

-

Chemicals: Used in the production of carbon black and titanium dioxide pigment.

What is CPC? A Closer Look at Calcined Petroleum Coke

CPC is the value-added product of calcining Green Coke. Its properties are essential for high-performance applications:

-

Function: Increases electrical conductivity, decreases volatile matter, and increases density.

-

Critical Parameters for Anode Production: Extremely low content of heavy metals (Vanadium, Nickel), low Sulfur (typically < 0.8\%), and high fixed carbon .

Petcoke vs. Coal: Can Petcoke be used instead of Coal?

Yes, Petcoke can be used instead of Coal in many industrial and power generation applications (cement kilns, power plants) because of its higher calorific value.

| Feature | Petroleum Coke (Petcoke) | Coal |

| Origin | Crude Oil Refining Residue | Mined Sediment/Rock |

| Calorific Value | High (typically > 8,000 kcal/kg) | Medium to High (varies widely) |

| Ash Content | Very Low | Medium to High |

| Structure | Highly variable (Sponge, Needle, Shot) | Layered/Sedimentary |

Comparison of Major Petcoke Grades

This table summarizes the core differences among the major types of Petroleum Coke, highlighting their properties and applications:

| Grade Name | Structure/Morphology | Key Impurity Level | Primary Production Process | Main Application | Market Value |

| Needle Coke | Long, Needle-like, Highly Crystalline | Ultra Low Sulfur/Metals | Delayed Coking (Special Feedstock) | Graphite Electrodes (Steel EAF) | Highest |

| Sponge Coke | Porous, Irregular Lumps | Low to Medium Sulfur/Metals | Delayed Coking (Standard Feedstock) | Aluminum Anodes, Fuel | Medium/High |

| Shot Coke | Spherical, Hard, Dense | High Sulfur/Asphaltene | Delayed Coking (Poor Feedstock) | Fuel (Cement Kilns, Power Plants) | Low |

| Green Coke | Raw, Unprocessed | High Volatile Matter/Moisture | Delayed Coking | Fuel, Raw Material for Calcining | Medium/Low |

| Calcined Coke (CPC) | Denser, Low Volatile Matter | Ultra Low Volatile Matter | Calcination (Secondary Process) | Pre-baked Aluminum Anodes | High |

Is Petroleum Coke Toxic? Environmental Concerns

Petroleum coke itself is a stable carbon solid and is not acutely toxic. However, environmental and health concerns arise primarily from:

-

Emissions during Burning: High-sulfur Petcoke releases significant Sulfur Dioxide (SO2) and nitrogen oxides (NOx), major air pollutants.

-

Trace Metals: Impurities like Vanadium and Nickel can be released during combustion or leach from stockpiles, posing long-term environmental risks.

-

Dust/Particulate Matter: Handling and stockpiling can create fine carbon dust, which is a respiratory irritant.

Excellent post. I was checking continuously this blog and I’m impressed!

Very useful info specifically the last part :) I care for such

information a lot. I was looking for this certain info for a

long time. Thank you and good luck.

Stop by my web site … convertisseur youtube mp3 download

Thanks so much for your kind words! We’re really happy to hear you found the post useful, especially the last section. It’s great to know we could provide the information you’ve been looking for.

We appreciate you stopping by our site.

The section on production methods and grade differences, especially the comparison of sponge, needle, and shot coke, was very enlightening for me, as I’m interested in technical details. Explaining what each type of coke is suitable for (like aluminum anode production or graphite electrodes) really helped me understand the topic more deeply. Great job!”

A great deep dive into Petcoke morphology. It’s crucial to emphasize that for Anode Grade Coke, the Silicon and Vanadium levels are as critical as the Sulfur content. In the calcination process, if the Green Coke has high metallic impurities, even high-temperature calcining won’t make it suitable for premium aluminum smelting. Does Universal Trades offer pre-calcined (CPC) options with guaranteed Vanadium levels below 250 ppm for sensitive electrolytic cells?

Hello Dr. Vane! You hit the nail on the head. Metallic impurities like Vanadium and Nickel act as catalysts for oxidation in aluminum anodes, which is why we are extremely selective with our feedstock. To answer your question: Yes, our Calcined Petroleum Coke (CPC) portfolio includes low-vanadium grades specifically tailored for high-purity smelting. We ensure that through our rigorous $CPC$ processing, the real density and vibration packed density are optimized for maximum anode life.